Blogs

April 24, 2025Ready, Set, Foam Expo!

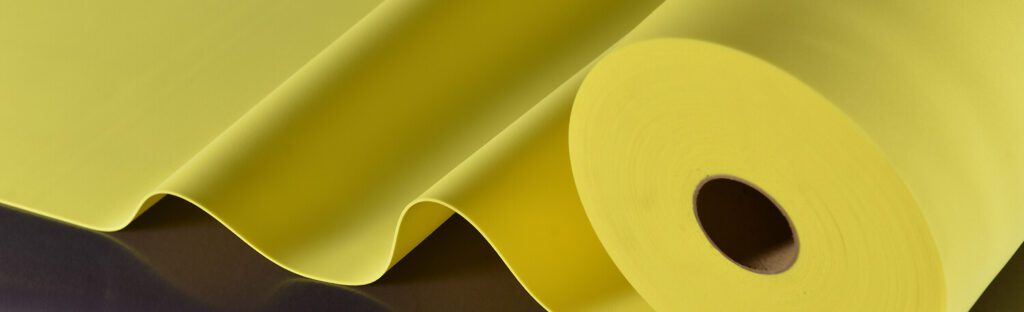

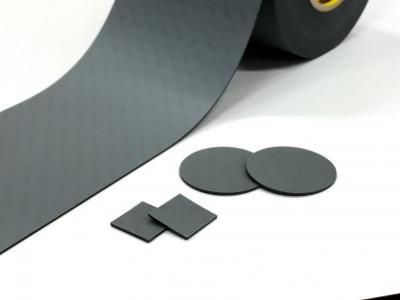

December 29, 2024Ensolite IR Series: Durable, Cost-Effective Foam for Industrial Gasket Applications

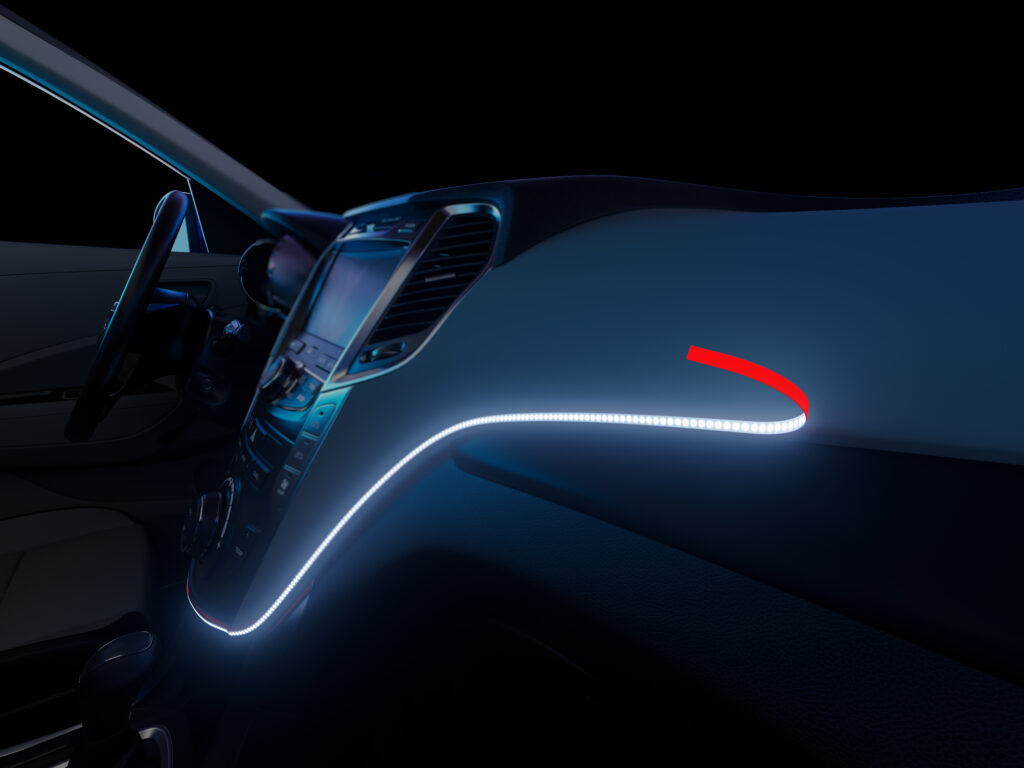

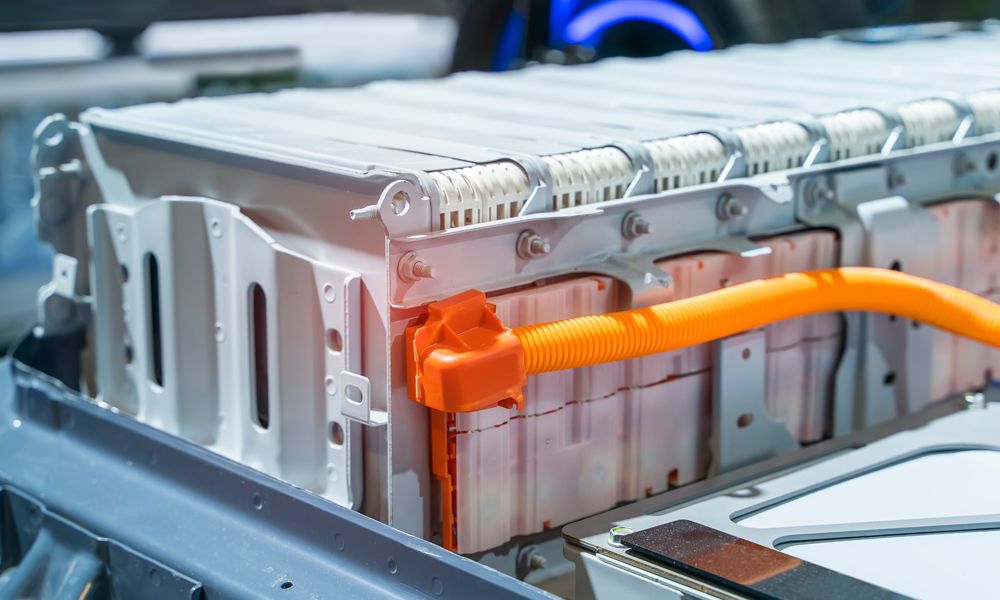

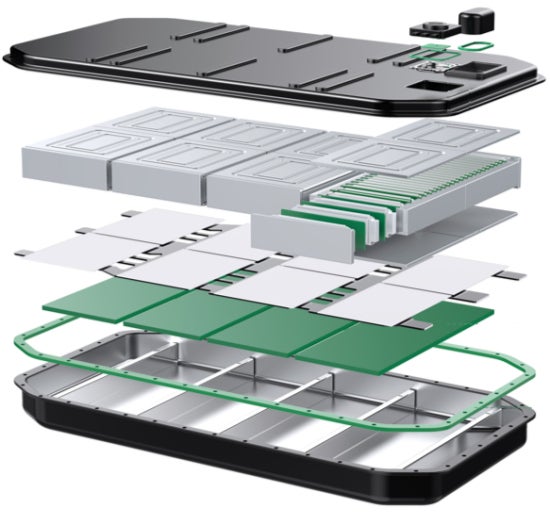

December 21, 2024Optimize EV Battery Performance with PORON® EVExtend® Foam Pads

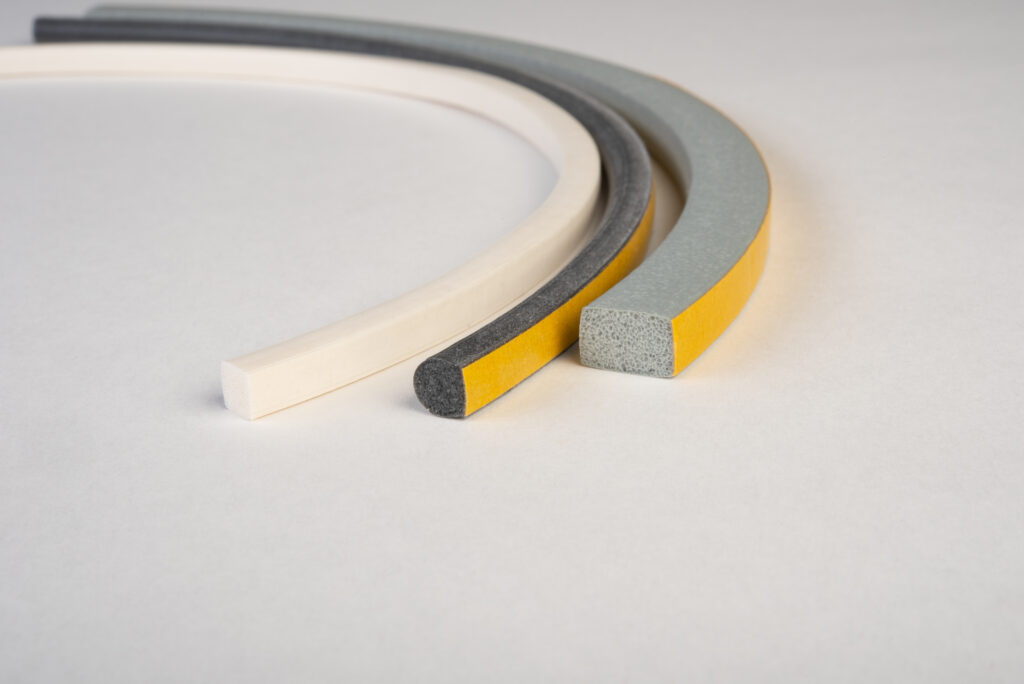

November 5, 2024Your Guide to Sourcing Custom Silicone Sponge Extrusions

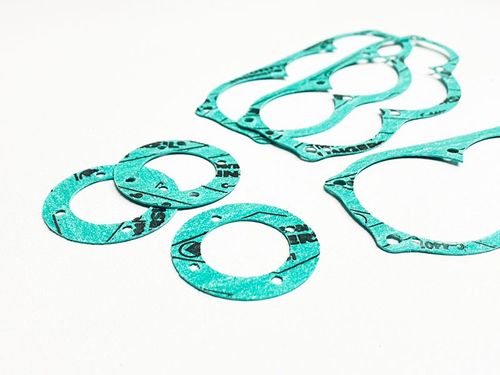

October 7, 2024Compression Set in Gaskets: What It Is and How to Prevent It

September 29, 2022Top 5 Considerations When Selecting Adhesives for Custom Gaskets

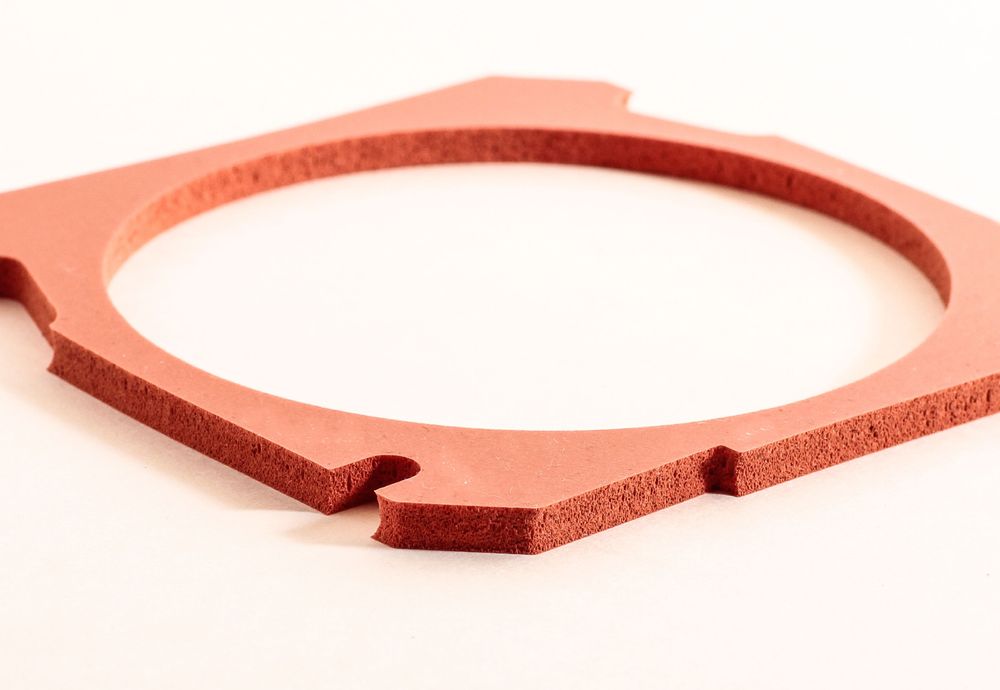

September 29, 2022Which Properties of Neoprene Make it a Good Choice For Gaskets?

September 29, 2022Top 5 Factors to Consider When Choosing Custom Gasket Materials

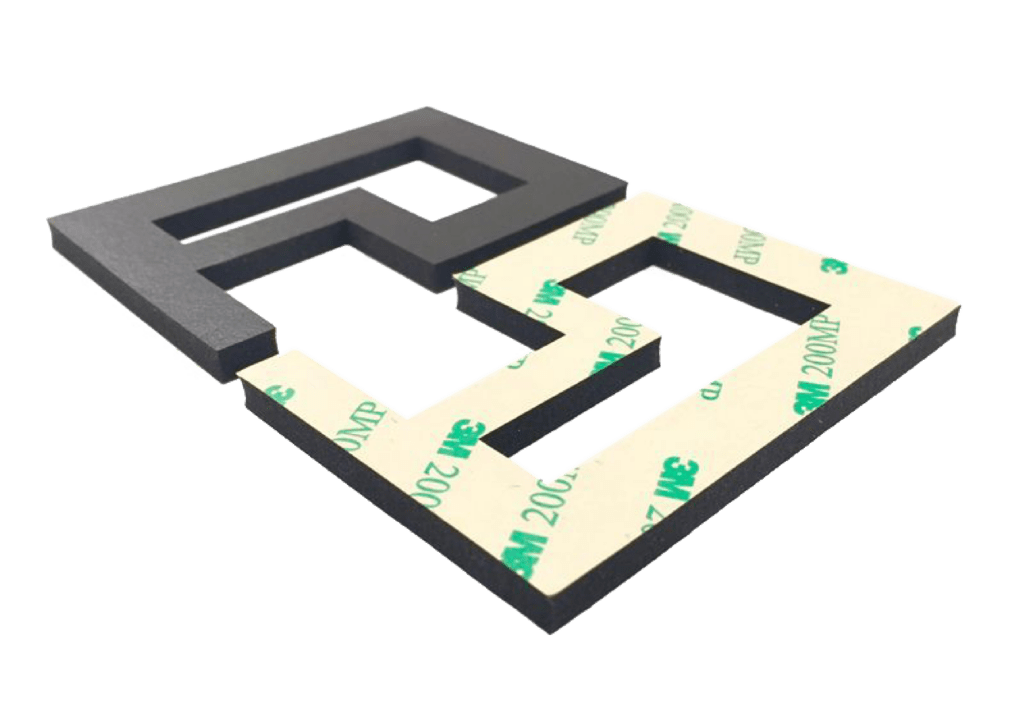

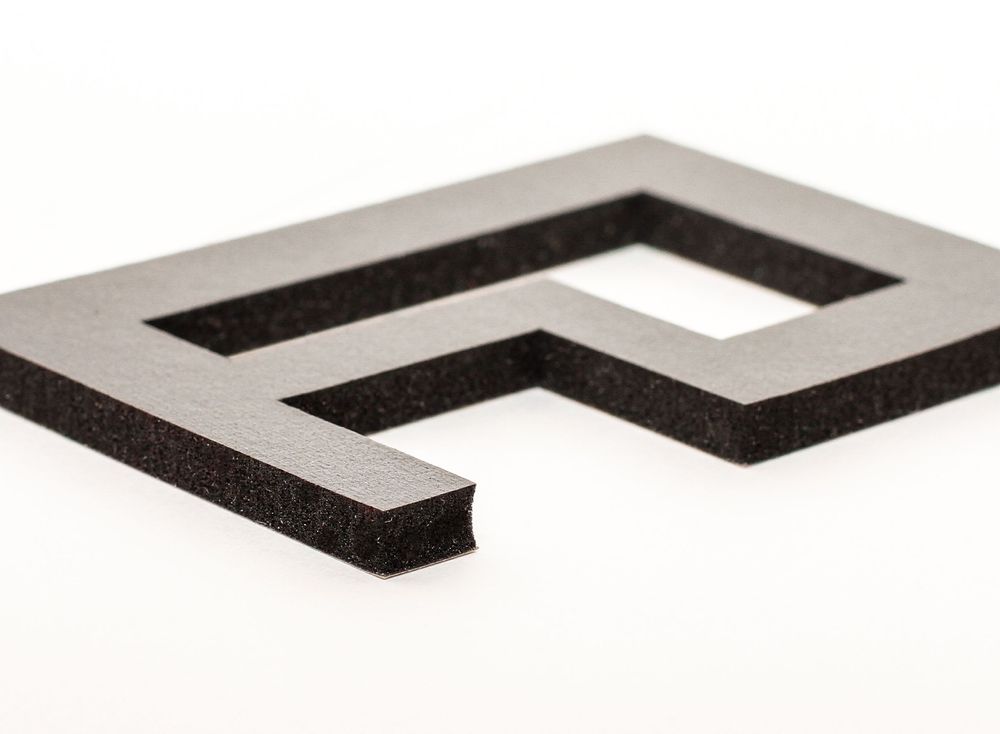

September 29, 2022Journey of a Gasket: How SRP Completes Your Custom Gasket Order

September 4, 2022Gaskets vs Seals: What’s The Difference and Why Does It Matter?

September 4, 2022Selecting the Best PORON® Foam for Long-Term Compression Recovery

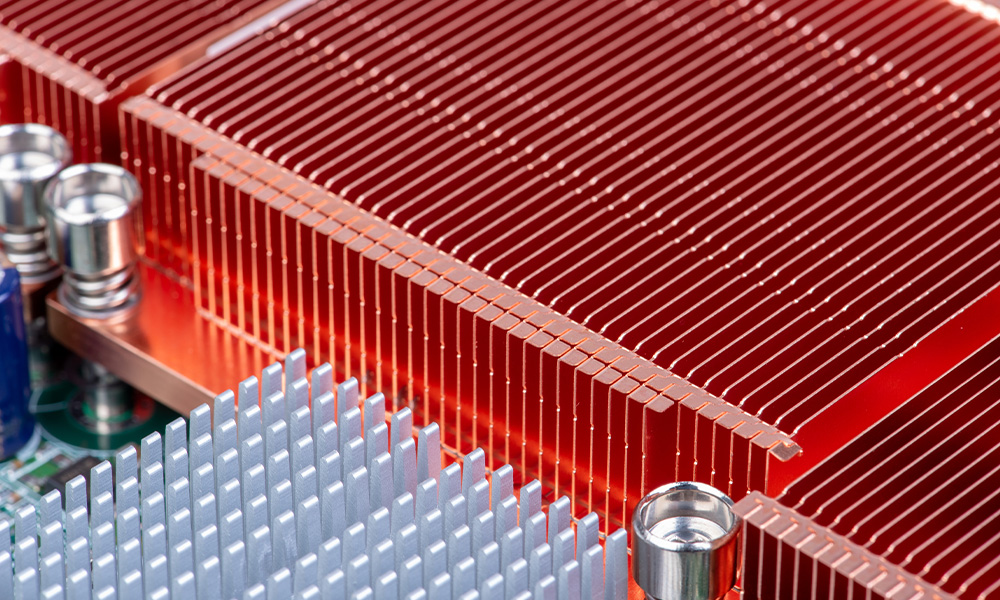

September 4, 2022What to Consider When Designing an EMI Shielding Gasket

September 4, 2022Guide To Rubber Gasket Materials That Can Take The Heat

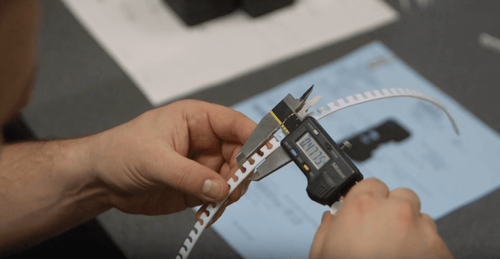

September 4, 2022Save Time and Money on Custom Gaskets by Optimizing Tolerance

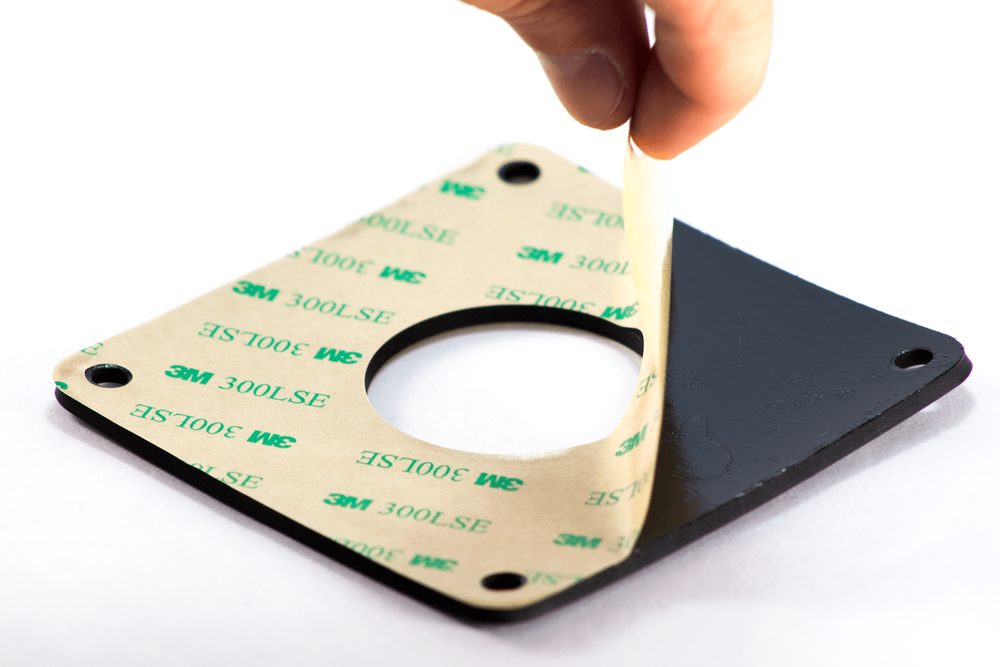

September 17, 2021Pressure-Sensitive Tape vs. Liquid Adhesive: Which Is Best For Gaskets?

July 16, 2021A Quick Guide To Gasket Adhesive Tapes

March 4, 2020Foam Expo North America 2020

April 4, 2019SRP Zhuhai Launches New Website

February 12, 2019Tradeshow Announcement: Foam Expo 2019

November 6, 2017SRP Launches New, User-Friendly Website

October 18, 2017Rogers BISCO® SIlicone Foam: Superior Resistance to Compression Set, Heat and EMI Interference

October 18, 2017A World without Custom Gaskets

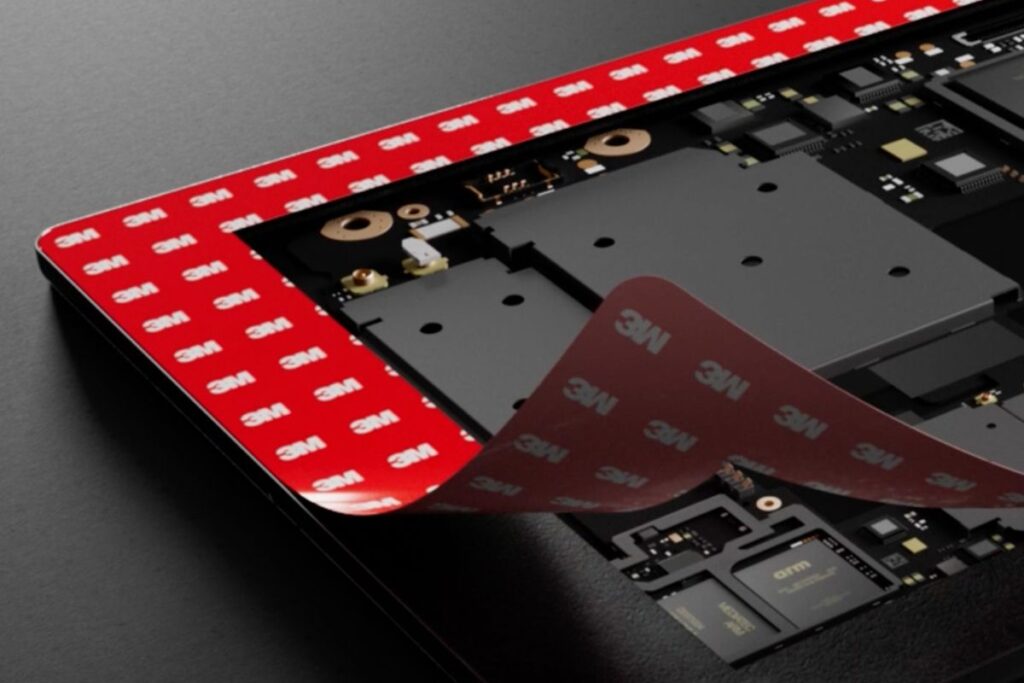

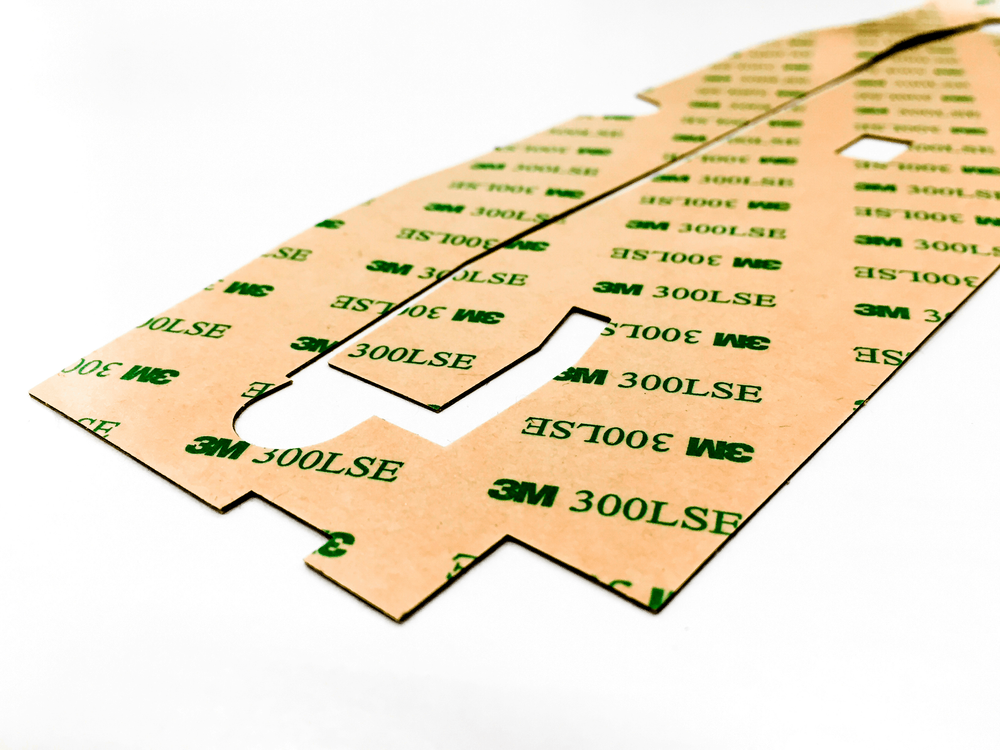

October 18, 2017Custom 3M™ Adhesive Tape and Its Benefits

May 30, 2017Why Choose SRP as Your Custom Gasket Supplier?

May 26, 2017Designs and Innovations in Porous Materials

March 3, 2017Foam Expo Wrap-Up

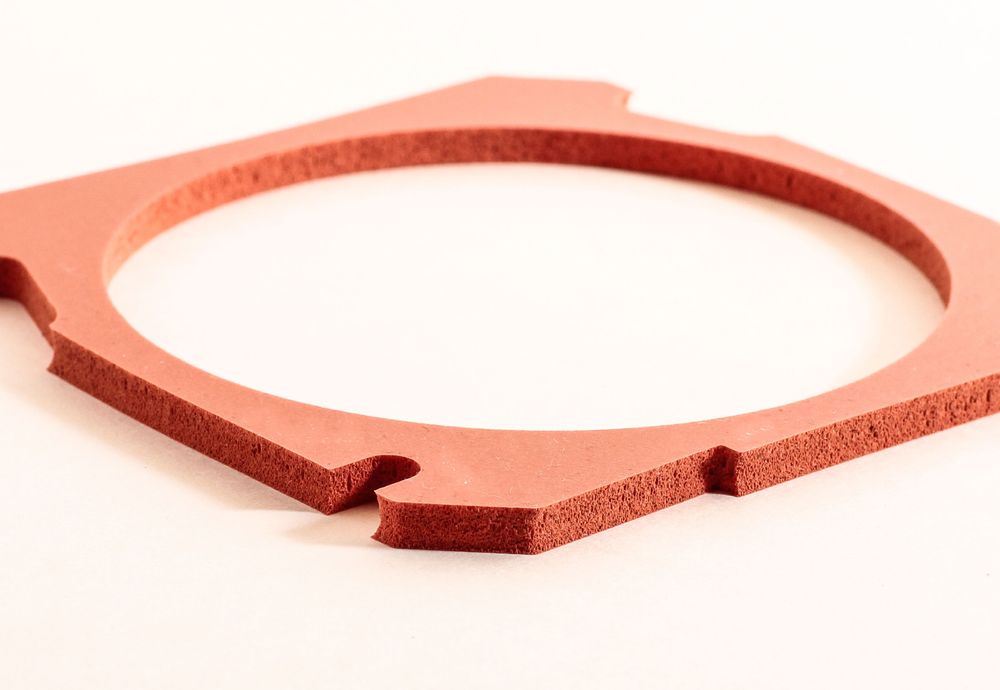

January 23, 2017Custom Silicone Gaskets: Designed & Manufactured for Durability

January 20, 2017SRP Announces Participation at Foam Expo Trade Show

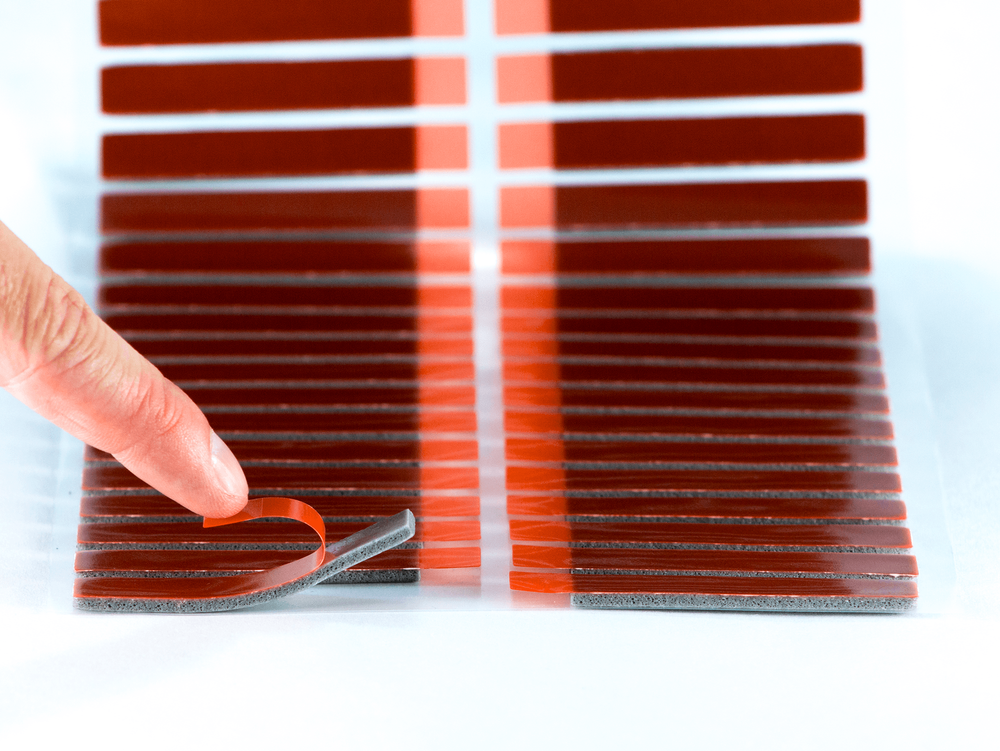

September 15, 2016Characteristics and Benefits of 3M™ Double Coated Tapes

September 12, 2016Comparing your 3M™ Specialty Adhesive Tape Options

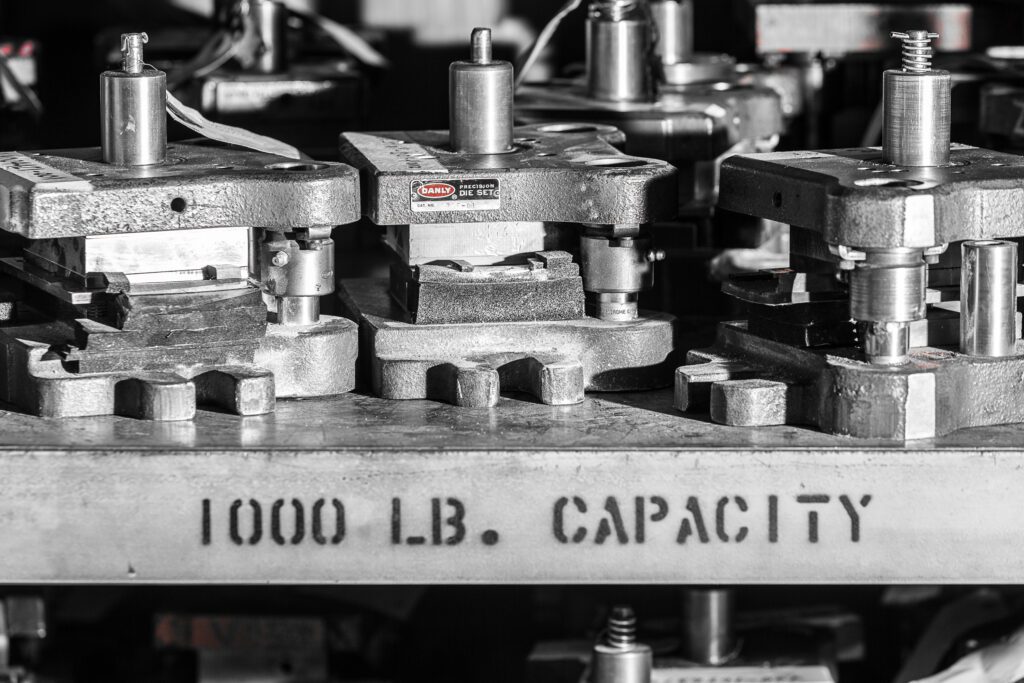

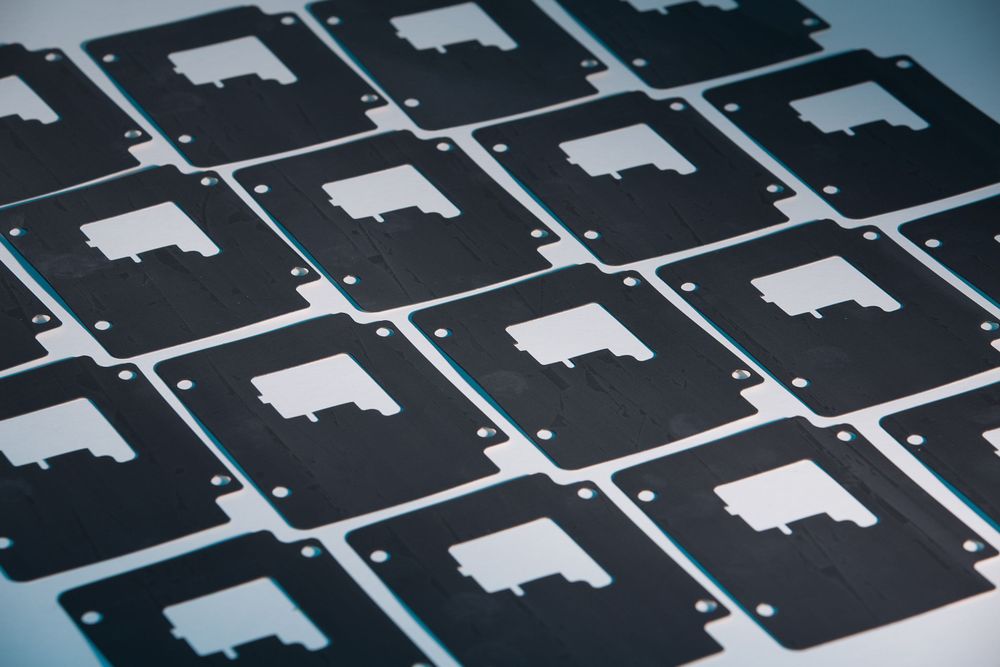

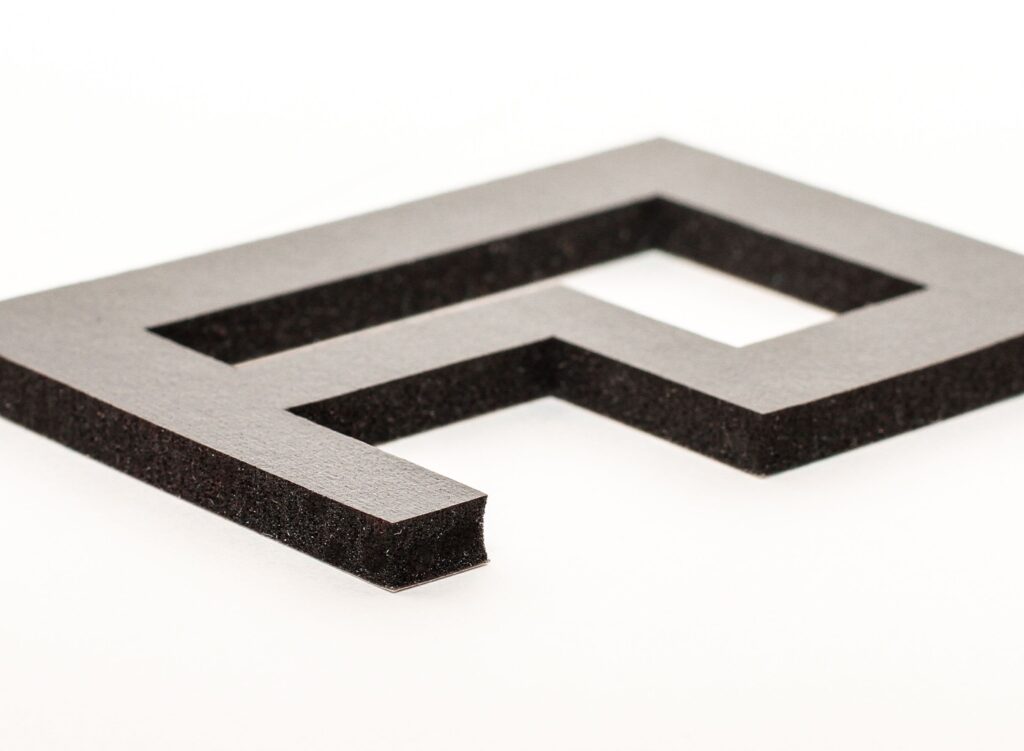

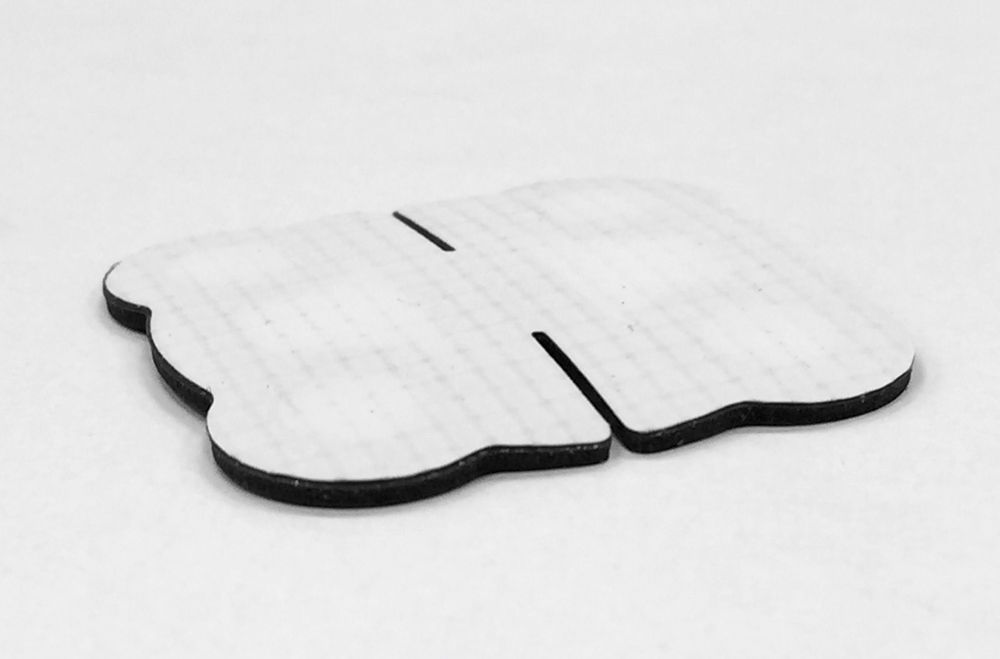

September 6, 2016High Quality Precision Die Cutting

July 25, 2016SRP Zhuhai 10th Anniversary Celebration

June 29, 2016One Decade Later

May 17, 2016D2P Show Round #2: A Success