Designs and Innovations in Porous Materials

PTFE is a very diverse and versatile material being used in a variety of applications including electronic, medical, industrial and many others. PTFE is inert, and what this means is that it is unreactive to most chemicals and extremely heat resistant with temperature limits of 500° F.

Porex porous PTFE materials not only offer excellent thermal, electrical, mechanical, and chemical properties, they also offer superior control over pore size, permeability, water entry pressure, and thickness. These properties make this PTFE an ideal choice for a wide variety of demanding applications requiring a combination of these properties. The primary function of these materials is to provide protection to sealed products from dust and moisture while allowing the enclosure to vent or to allow gas movement while protecting the device.

Engineers have used Porex PTFE membranes to create a wide variety of products, from battery and fuel cell components to key fob vents. If your business has a need for innovations using porous materials, it would be beneficial to talk to an engineer about Porex PTFE membranes for your application.

Other applications for these materials include:

- Sensors

- Automotive Electronics

- Portable Electronics

- Medical Equipment

- Acoustics

- Lighting

- Energy Generation & Storage

- And many more!

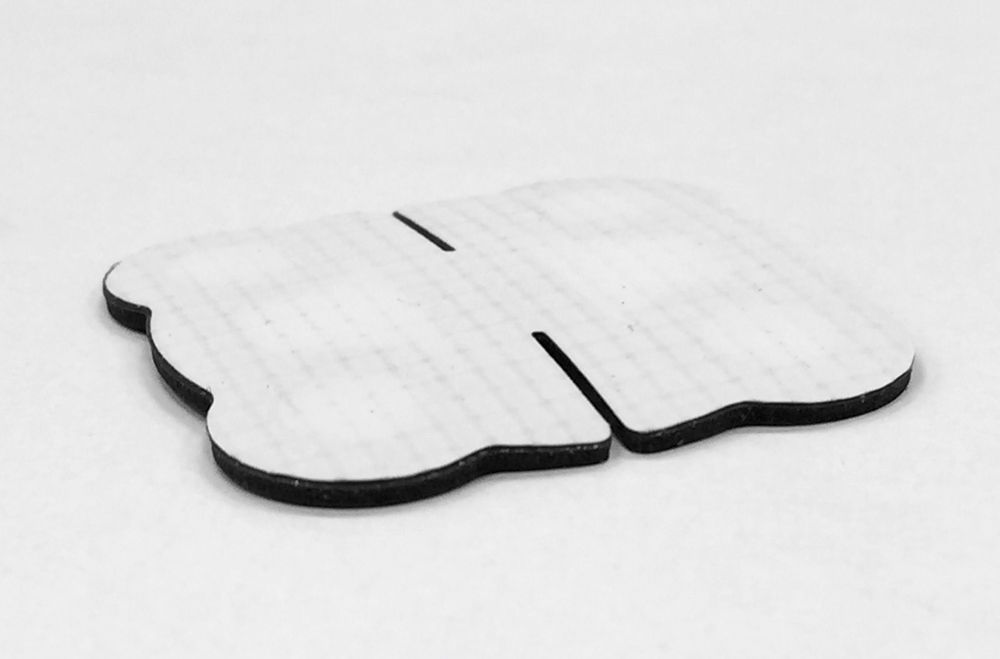

Custom Converted Porex PTFE

Porex PTFE materials can be converted in a variety of ways to best suit your specific application. At SRP, we commonly convert these materials using our specialized die cutting equipment. Depending on the application, we can fabricate PTFE in a number of different ways by either die cutting raw material, adding an adhesive backing to parts, supplying parts on a low tack release liner for quick and easy handling, or adding a zoned elastomer to make a custom Porex gasket.

These innovative products can solve many business challenges, as they are durable, long lasting, and designed for applications that require a long life. Contact our engineering and sales teams today to learn more about how Porex PTFE can add innovation and performance to your next project.