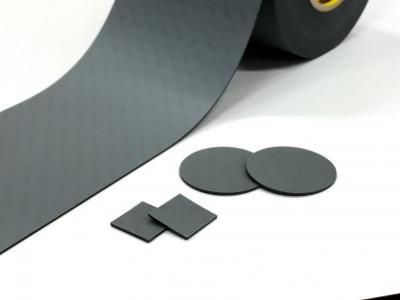

Material Highlight: 3M Bumpon Resilient Rollstock

What is 3M Bumpon?

3M Bumpon is a material that you more than likely come in contact with on a daily basis, but you probably never even knew it existed. 3M Bumpon Resilient Rollstock is a self-adhesive rubber bumper designed to be used as feet, stops and spacers on handheld or desktop computers, calculators, electronic housewares, electronic equipment, desktop items and medical devices.

The rollstock format is excellent for die-cut shapes with various thickness requirements for gasket applications to fill gaps, dampen noise and reduce vibration.

Product Protection

3M Bumpon features include:

- Easy application with 3M pressure sensitive adhesives

- High skid-resistance.

- Won’t scratch or stain surfaces

- Reduces vibration and noise

- Will not crack or harden

3M Bumpon for a Variety of Applications

Application Ideas for 3M Bumpon include:

- Die cut for gasket application

- Anti-rattle spacer to fill gaps, dampen noise and reduce vibration

- Skid-resistant surface on floor

- Cushions or spacers within electronic devices

- Selective masking for sandblast operation

- Spacer or stop to prevent surface damage

- Door kick pads

- Corner protection strips

- Die cut cushioning stop for cabinetry

3M Bumpon is a highly convertible material, making it easy for us to custom fabricate. This material can be custom cut into virtually any shape imaginable. SRP’s processing capabilities for this material includes: Die Cutting, Flash Cutting, Rotary Die Cutting, Waterjet Cutting, Laser Cutting, and Laminating.

————–

If you have any questions or inquiries concerning 3M Bumpon, please do not hesitate to call us at 847-593-5630, or email us at info@srpco.com. We will be happy to answer any questions you may have, or assist you in assuring you are choosing the right materials.