Enhancing EV Battery Systems With Advanced Gaskets and Seals

At SRP, we understand the significance of selecting the best-performing materials for fabricating custom gaskets and seals for EV battery systems.

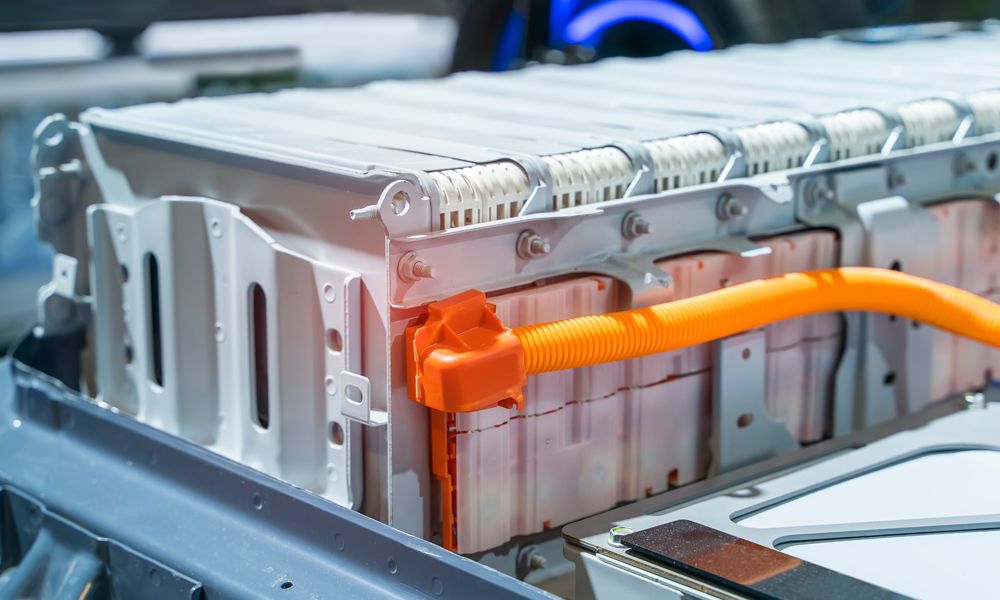

The transportation industry is on the cusp of a major evolution, with electric vehicles (EVs) leading the way. As the market continues to accelerate, the choice of gasket and sealing materials becomes increasingly critical. We’ll explore the reasons behind the shift from internal combustion engines to lithium-ion-powered cars and delve into the essential role gaskets and seals play in ensuring the performance and safety of EV battery systems.

The growth of the electric vehicle market

To set the stage, let’s consider the remarkable growth of the electric vehicle market. As of October 2022, there were 1.9 million EVs in operation in the United States, accounting for 0.7% of the total 281 million vehicles on the road. Projections by S&P Global Mobility suggest that by 2030, four out of every ten vehicles on the road will be electric.

This surge can be attributed to various factors, including government incentives, expanding battery manufacturing capacities, increased consumer demand for eco-friendly options and the declining costs of lithium-ion batteries.

The importance of battery performance and safety

With the future of transportation at stake, ensuring the success of EVs is paramount. Battery performance and safety are pivotal factors in achieving this success by preventing thermal runaway, achieving consistent and reliable battery range, and maintaining charging performance. EV battery systems must withstand demanding conditions, requiring rugged gaskets and seals that protect against temperature extremes, UV exposure, wind, moisture ingress and sudden impacts.

Key performance criteria for gaskets and seals in EV vehicles

To meet the performance and safety requirements of EV battery systems, gaskets and seals must excel in several areas. These criteria include:

- Vibration absorption

- Isolation of extreme heat or fire incidents

- Optimization of overall performance

- Protection against temperature impact and environmental ingress

- Thermal insulation for heat-sensitive components

- Fire protection and shielding against EMI interference

- Compression set resistance throughout the product’s lifespan

SRP: Your Trusted Resource for Custom Gaskets and Seals

At SRP, we understand the significance of selecting the best-performing materials for fabricating custom gaskets and seals for EV battery systems. Through our preferred partnerships with top brands of adhesives, films and elastomeric materials, we ensure the highest quality die-cut components. Our experienced team can fabricate these materials to your exact specifications and deliver them directly to you.

Applications of gaskets and seals in EV batteries

We provide a range of die-cut solutions for gasket and sealing applications for EV batteries, including:

- Battery packs

- Sealing for battery modules

- Battery covers

- Venting caps

- Cooling plate and liquid delivery system

- Battery cells

- Terminal isolation

Gaskets and seals play a pivotal role in meeting the performance and safety requirements of EV battery systems. By selecting the right materials for your components and die-cutting them to your exact specifications, we can help ensure the longevity, reliability and efficiency of EV battery systems. To learn more about our offerings and how we can enhance your EV battery systems, contact the experienced team at SRP.