expanSil™ Silicone Sponge Extrusions

Through our Preferred partnership with Rogers Corporation, SRP has access to Silicone Engineering’s expanSil™ silicone sponge extruded products that we are able to offer to our customers.

Why Engineers Trust expanSil Silicone Extrusions

- Consistent performance across grades and densities

- Low compression set for long-term sealing reliability

- Wide operating temperature range for demanding environments

- Excellent resistance to ozone, UV, and weathering

- Closed-cell construction for effective sealing and low water absorption

- Regulatory-compliant material options (FDA, UL94, FAR/JAR, ASTM, AMS)

expanSil™ Silicone Sponge Extrusion Formulations

A broad range of silicone sponge extrusion families engineered for sealing, insulation, and long-term performance across demanding applications.

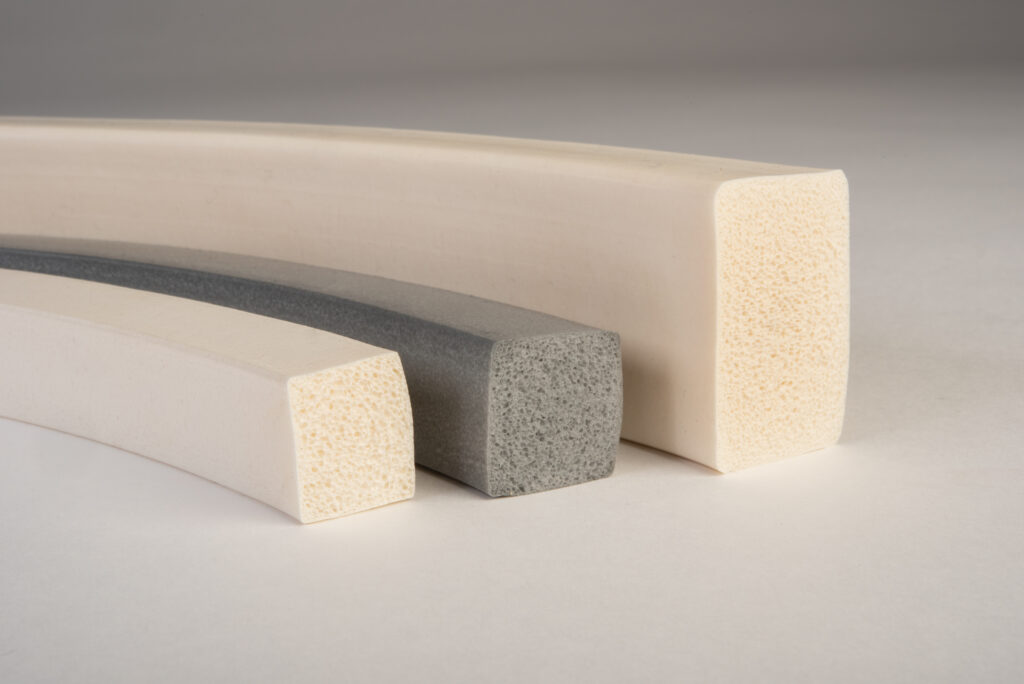

expanSil™ Silicone Sponge Extrusion Products

Silicone Sponge Extrusions are available in a variety of sizes, densities, colors, and can be manufactured as a cord, profile, section or tubing.

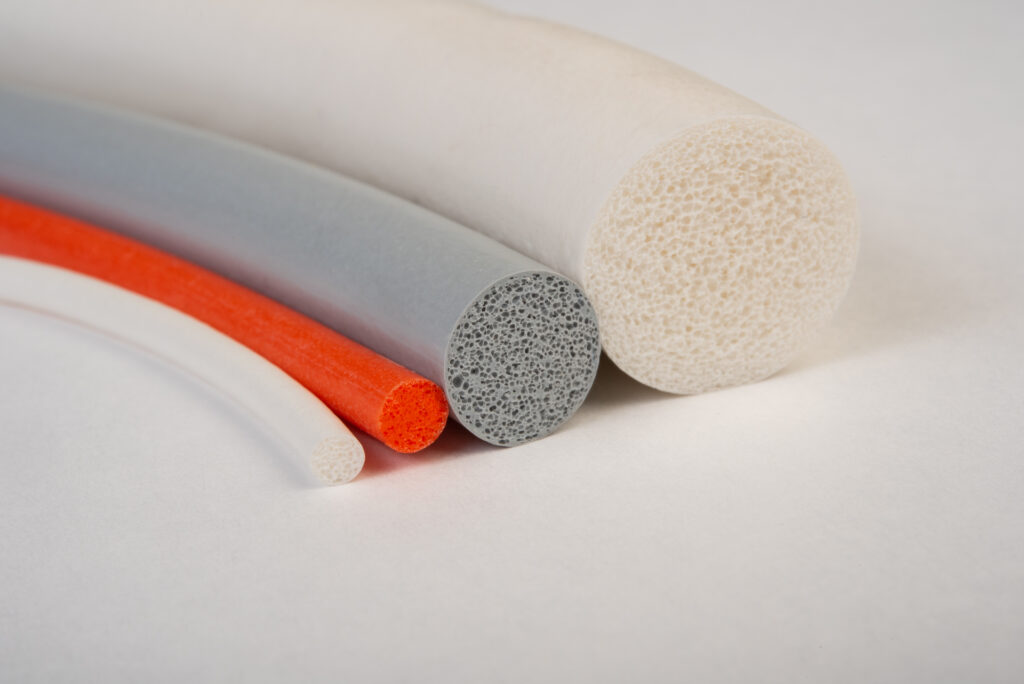

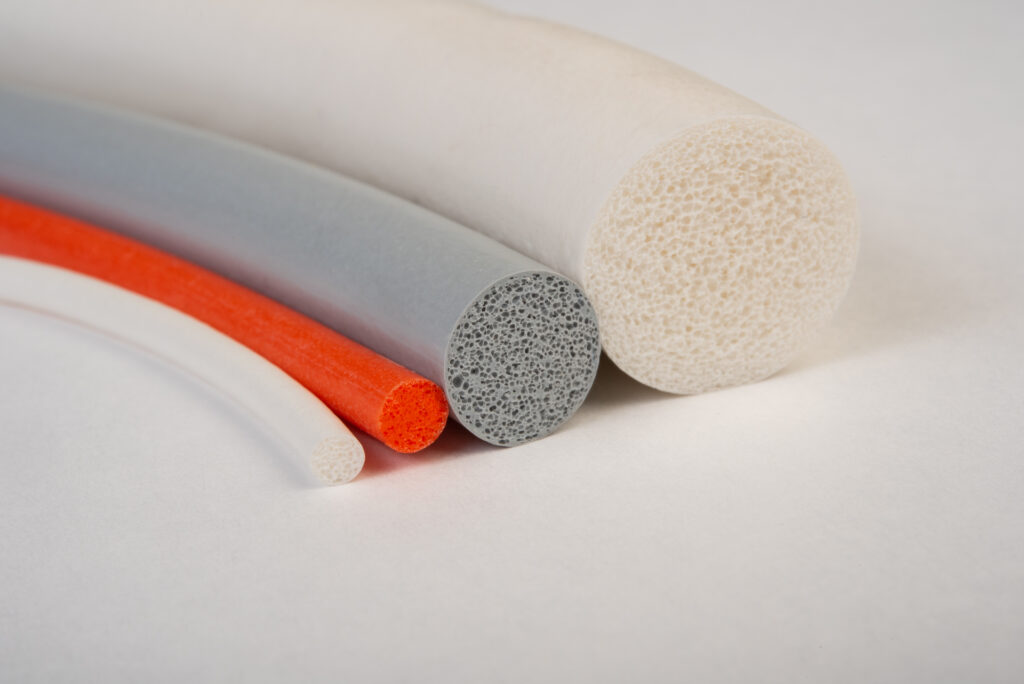

expanSil™ Silicone Sponge Cord

Silicone sponge cord extrusions can be produced in diameters ranging from .079″ to 1.97″ (2mm to 50mm), and densities from 12 lb/ft³ to 33 lb/ft³ (200kg/m³ to 530 kg/m³). Thermally stable over a wide range of temperatures from -76°F to 446°F (-60°C to 230°C).

The cord is often cut to length and joined to form rings. Popular applications for these include use as a gasket in applications that require superior sealing properties in harsh environments.

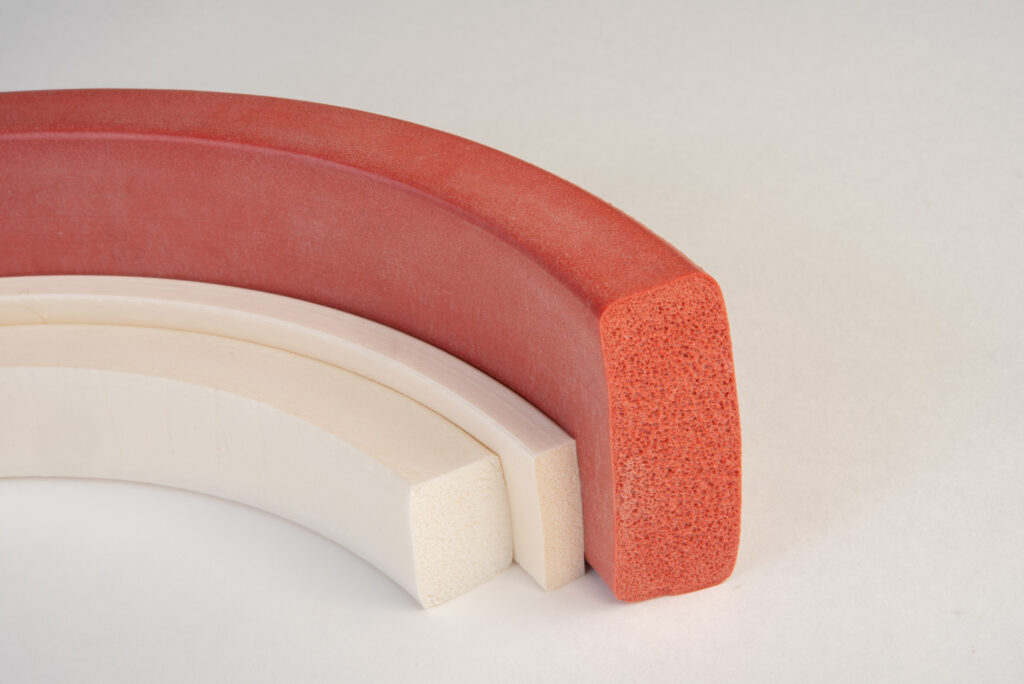

expanSil™ Silicone Sponge Profile

Silicone sponge profiles can be tailored to exact drawings and designs required for sealing applications in a range of industries. From simple ‘P’ profiles to more complex shapes.

Densities from 12 lb/ft³ to 33 lb/ft³ (200kg/m³ to 530 kg/m³). Silicone sponge is closed cell, has excellent Ozone, UV and Weathering resistance, and is thermally stable over a wide range of temperatures -76°F to 446°F (-60°C to 230°C).

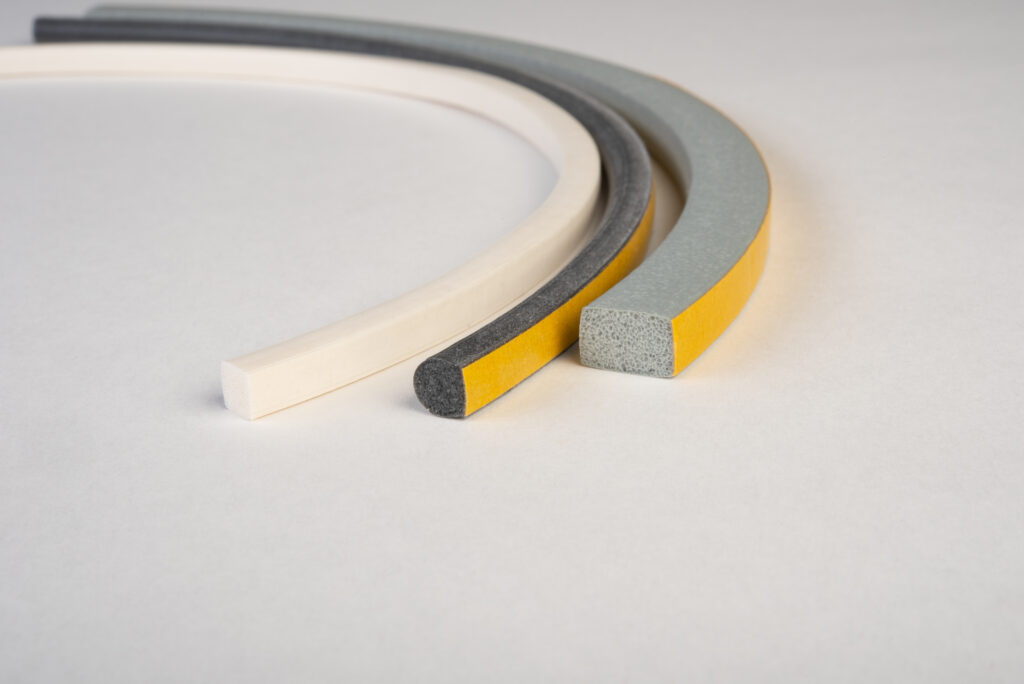

expanSil™ Silicone Sponge Sections

Silicone sponge sections are available in square from .079″ to 1.97″ thick (2mm – 50mm) and rectangle forms from .098″ to 1.57″ thick, and up to 3.93″ wide (2.5mm – 40mm thick, up to 100mm wide). Densities range from 12 lb/ft³ to 32 lb/ft³ (200kg/m³ to 530 kg/m³). A variety of speciality grades such as Flame Retardant and Low Toxicity are available.

Sections can be supplied in coils, cut lengths or fabricated into rings of various sizes using silicone extension joining equipment. Applications include channel seals, where the section is located in a channel to provide a sealing surface.

expanSil™ Silicone Sponge Tubing

Silicone sponge and foam tubing (closed cell) available in general purpose and almost all of the special formulation grades. Silicone sponge tubing can be produced from an inner diameter (ID) from .197″ up to 2.75″ (5mm up to 70mm) and an outer diameter (OD) of .390″ up to 3.93″ (10mm up to 100mm). Available densities include 15lb/ft³ (250kg/m³), 25 lb/ft³ (400kg/m³), and 33 lb/ft³ (530kg/m³).

Custom expanSil™ Silicone Sponge Extrusions

By working closely with the customer we firstly assess the application and problem (if any) that is being experienced. We can then design the profile needed to perform and also the correct silicone grade to fit the application. Following production of a prototype, the design will be tested to ensure the product performs exactly as specified.

How can we help?

Please submit the form and a member of our team will be in touch with you shortly