Switching To A More Cost Effective Material, While Maintaining Optimum Performance

Challenge

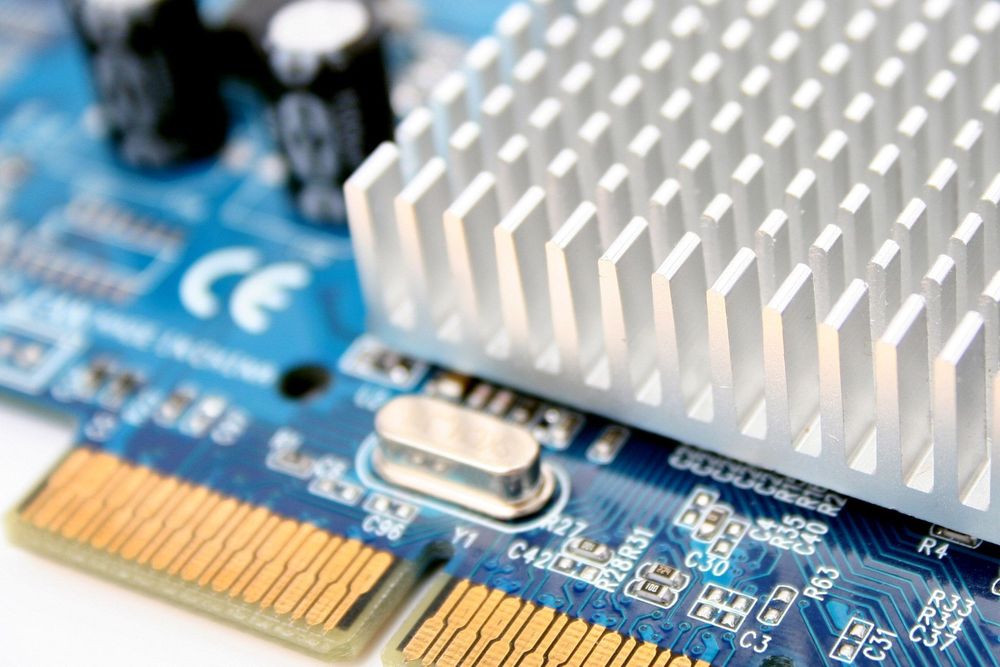

This electronics manufacturer was using a silicone interface pad on a heat sink for a small electronics application. The purpose of the interface pad is to provide a preferential heat transfer path between heat generating components to keep the product from overheating, which will eventually damage the product and rendering it useless.

The challenge, however, was not in the functionality of the product, but in the expenditure of the application. Our customer was looking to be more cost effective with their products.

Solution

After understanding the temperature specifications of the application, SRP realized that the performance of the silicone adhesive they were currently using was a lot more than what was required.

Our solution was to switch to the 3M™ 5571 Acrylic Thermal Interface Pad to be more cost effective, while continuing to maintain the same performance of the Silicone Pad.

Results

After thorough testing of the new 3M™ 5571 Acrylic Thermal pads, our customer found that this material was more than enough performance to keep their products safe from the heat at a fraction of what they were spending with the silicone interface material.

Materials Used

- 3M™ 5571 Thermally Conductive Acrylic Interface Pad

Manufacturing Process

- Rotary Die-Cutting