Guide To Rubber Gasket Materials That Can Take The Heat

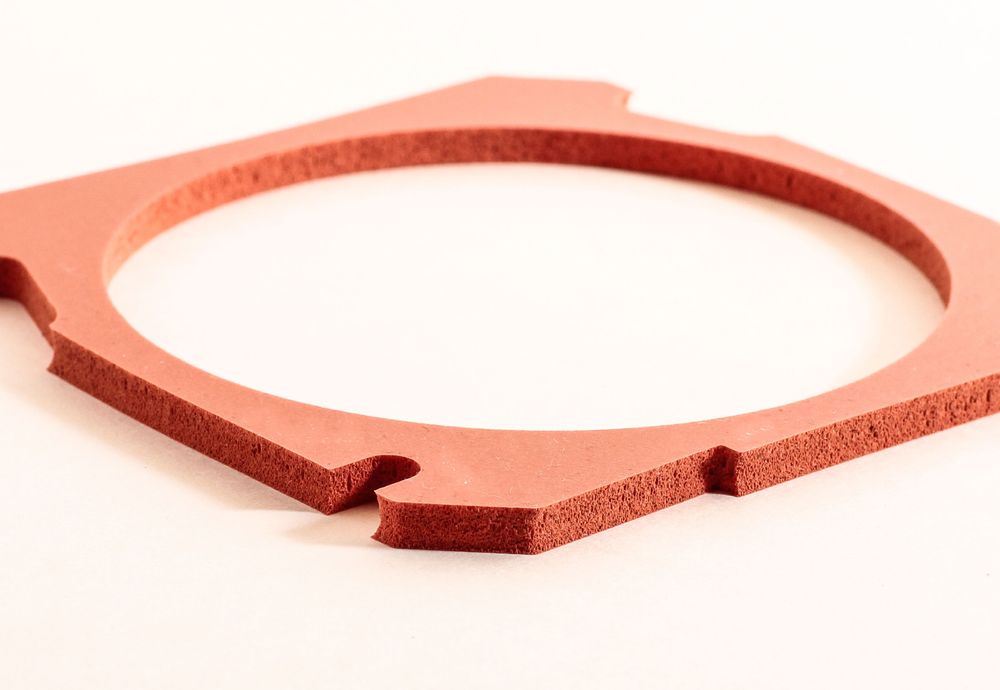

The gasket is a small and mighty component that holds everything together in your product. But when your rubber gasket also has to resist high heat, choosing the correct material can be a complex decision.

What to know when choosing heat-resistant rubber

Elastomeric materials are sensitive to temperature, light, oxygen, moisture, heat and mechanical pressure. When used in demanding applications like electrical enclosure gaskets, electrical magnetic interference (EMI) protection and battery powered electronics, it’s important to select materials that can stand up to these tough conditions. Doing so will ensure the longevity of the gasket, not to mention the safety of the end user.

High-temperature gaskets should be designed protect against will aging, cracking and holding a seal:

Thermal aging: If your product has to clear testing to meet ASTM standards, one may include thermal aging testing of your chosen rubber material. This provides the data on how your gasket would perform while resisting deterioration in high heat conditions.

It’s important to understand that if the material survives the thermal aging test, that doesn’t mean its performance abilities are intact.

Other measurements in standards testing include compression set testing along with tensile and elongation testing. These evaluate whether the high-temperature environment causes deformity in the material:

Compression set: This test shows much of the elastomeric properties a material retains after exposure to high heat. Longer tests can reveal if the high-temperature rubber gasket material is capable of maintaining its seal.

Tensile and elongation: This metric shows whether the materials can retain their normal breaking point when stretched with pressure.

[Read: Top 5 Considerations for Custom Gasket Materials]

What temperatures can rubber materials stand?

Compared to metal and composite materials, elastomeric materials have a lower operating temperature. As a rule, anything with an operating temperature of 350 degrees Fahrenheit is considered a high-temperature rubber gasket material. As a starting guide, here’s a list of some of the most common sheet elastomeric gasket materials we work with and their maximum operating temperature.

- Natural Rubber: 180 F

- Nitrile (Buna-N): 250 F

- Butyl: 250 F

- Neoprene: 220-280 F

- EPDM: 250-300 F

- Fluoroelastomer (also called fluorocarbon): 400 F (as high as 600 F for shorter periods)

- Silicone: 500 F

Fluorocarbon vs. silicone: What’s the difference?

When it comes to finding the perfect heat-resistant flexible material for your gasket, it often comes down to fluorocarbon and silicone. In addition to high heat resistance, the material should also hold up well to compression pressure and the weather.

Silicone is the standard when considering a high-heat rubber material for gaskets, as it can withstand operating temperatures up to 500 F before it starts to degrade.

[Explore our selection of silicone materials and Rogers BISCO.]

Fluorocarbons also withstand high operating heat up to 400 degrees. But fluorocarbons have a couple of advantages over silicone:

- Higher tensile strength, which would make it the better option for high-pressure applications.

- Higher resistance to fuels, solvents and chemicals.

When you’re selecting your materials for your custom gasket, the materials experts at SRP are here to help.

Learn more about our custom gasket and converter capabilities. Contact SRP and request a quote.