What Does a Custom Foam Gasket Cost? 3 Factors That Matter Most

Looking for a competitive edge? Getting strategic with cost savings is a reliable path. Because in the realms of manufacturing and product development, the unexpected can happen at any time. Prices fluctuate, shipments get delayed and industry requirements are continuously changing.

At SRP, we’ve been in the business of manufacturing custom gaskets since 1951. With our decades of experience, we have a few time-tested strategies to help you gain control over gasket costs.

What has the biggest impact on gasket cost?

Looking for ways to make custom foam gaskets more cost-efficient? These three areas have the largest impact on your per-unit costs.

- Selected materials

- Production volume

- Turnaround time

The following will show how these areas impact the cost of custom gaskets and how you can exert some control to get the greatest value.

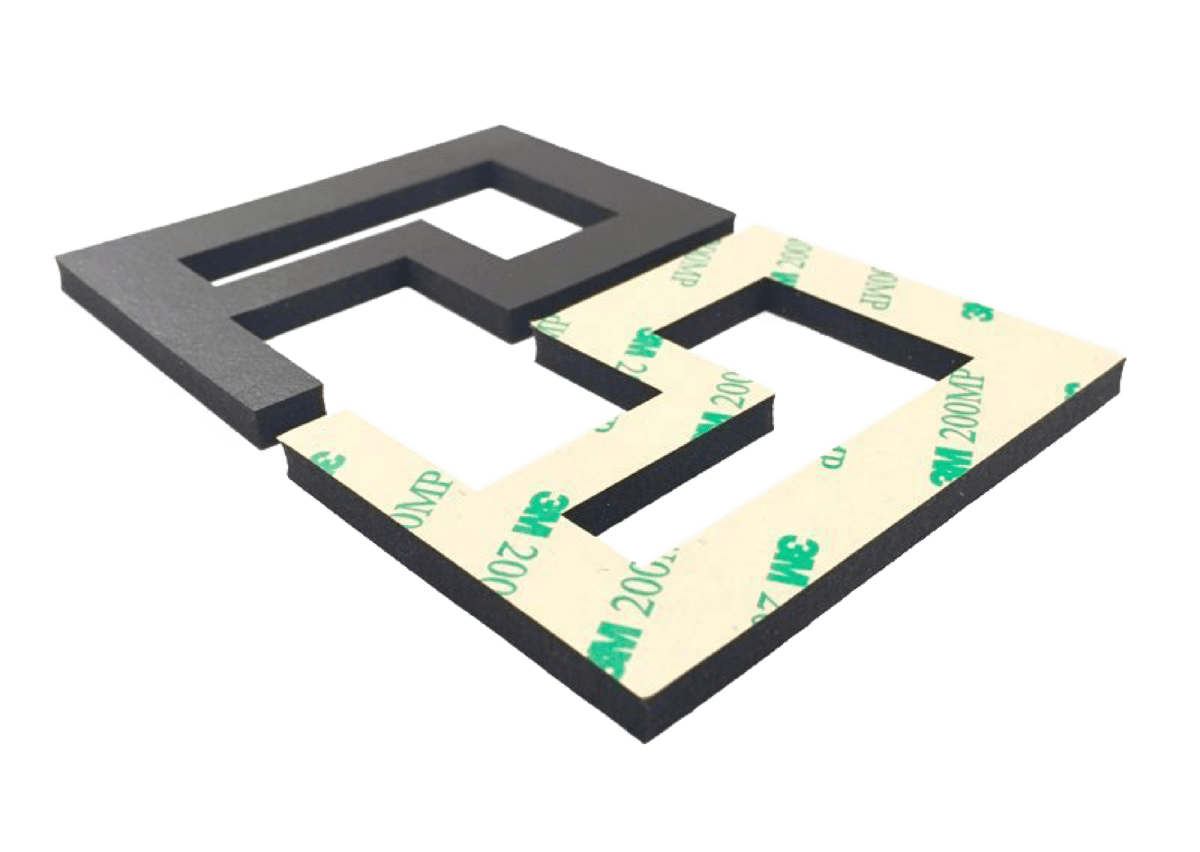

1. Selected Materials for Custom Gaskets

More than any other factor, the type of foam gasket material and pressure sensitive adhesive will have the greatest impact on your per unit cost. But there are some areas where it’s possible to exert more control.

And this is where we at SRP can help you.

Material analysis for quality

Quality matters when choosing foam materials and gasket tape.

Selecting materials based on price alone can result in premature gasket failure, leading to higher costs in the long run (along with a hit to customer goodwill). And yet, there’s no need to pay premium prices for premium materials when the application only requires a standard material like an industrial EPDM or Neoprene, rather than a spec grade.

At SRP, our focus is value and quality. Our experts can help you identify a material that achieves the performance you’re looking for, whether it’s a gasket that seals against weather conditions or a heat-resistent rubber gasket materials.

Because at the end of the day, people want the best result, not necessarily the cheapest product.

Maximize your material yields

At SRP, our processes are designed to help you get the most yields per area of material. We use tools like computer-aided software with part nesting capabilities, so we can get the maximum number of parts per area of material.

Proactively prevent errors

Errors in die cutting can be costly. Choosing the right cutting method for a given foam material will prevent rework and ensure consistency and quality.

Our team is one of the most experienced in the business. That speaks to the strength of our team. Many of our people have been with us their entire careers. With that level of experience working for you, your projects will have a higher success rate and better outcomes.

Tolerance in soft materials

When you’re looking for a precision fit, it makes sense to ask for a close tolerance part, right? Depends on the material. For rigid materials like metals and hard polymers, a close tolerance cut makes sense.

However, when die-cutting soft, flexible materials, variation is inevitable. Typically, die-cut foams can accommodate a wider tolerance range than rigid materials and still function exactly how they’re designed.

Otherwise, if you don’t account for slight variances in die-cutting soft materials, a high percentage of perfectly good gaskets will end up getting binned.

Not sure how to calculate the best tolerance for your part? No problem! The experts at SRP can pinpoint the most cost-efficient means to create your gasket.

2. Production Volume of Gasket Orders

In manufacturing, every minute counts. That’s why we focus on keeping production time productive.

The die-cutting method is often tied into that. Some methods, like laser cutting and water jet cutting score high on precision. But unlike traditional die-cutting methods that can stamp shapes out of material, it takes longer to make a part. If you have a large volume, that can lead to cost increase.

To get a deeper understanding of how production impacts gasket cost, read our blog, Die-Cutting Methods for Custom Gaskets: Understanding The Pros and Cons.

3. Turnaround Time for Gasket Orders

A reliable cost control method is managing your production timeline. It pays to leave yourself a cushion. Otherwise, when deadlines get tight, you may incur extra costs to expedite production or express ship an out-of-stock material.

Fortunately, SRP has a precise system with cost estimates and a quick turnaround time. That gives the ability to offer lean lead times for many custom gasket orders, especially when they feature in-stock, readily available materials.

We pride ourselves on having the agility to accommodate special requests and deadlines. But at the end of the day, being proactive with deadlines will be a cost advantage for you.

Maximize Quality and Efficiency With SRP

SRP has the latest equipment and manufacturing expertise to achieve the best production efficiency and gasket quality for your order.

Ready to start your next project? Contact SRP today for expert advice, rapid quoting and high-performance gasket solutions.