Thermal gaskets: A guide to their benefits, functions and materials

A thermal gasket serves an important and specific purpose across many industries — particularly in applications where managing heat is critical to product performance and longevity. Though often overlooked, these gaskets play a vital role in ensuring the reliable operation of devices we use every day.

Why thermal gaskets matter

A thermal gasket is a compressible material that’s designed to contain and withstand heat, not transfer it — protecting sensitive components from overheating.

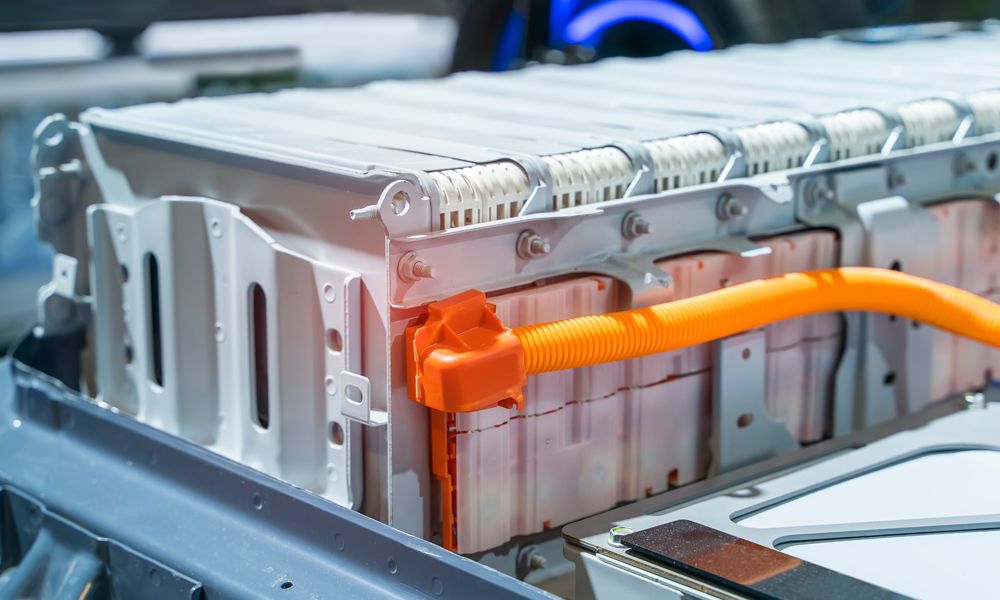

That heat shield makes thermal gaskets essential in a wide range of applications, including electronics, EV battery systems, power supplies, lighting systems and consumer appliances. By protecting sensitive components against heat damage, your product remains safe and operational.

Key functions of a thermal gasket: Heat insulation & sealing

High temperature gaskets are designed to withstand operating temperatures of 350 degrees Fahrenheit and above. They can be used to join and connect materials, while protecting through insulation and flame resistance.

Their ability to seal against environmental ingress makes them especially useful in compact, battery-powered electronic designs, where limited space increases the risk of thermal buildup. In these cases, thermal gaskets can be multi-functional — making them a high-impact solution in a small footprint.

Choosing the right thermal gasket material for your application

Thermal gaskets are designed to serve as a compressible, thermally resistant seal to protect components against heat intrusion. While gaskets are traditionally associated with sealing out contaminants, these can be made from materials that offer excellent resistance to flame and heat.

Standards and compliance: Select materials that are rated for UL 94 and ASTM E162, which tests flame spread for materials exposed to heat and flame.

Operating temperatures: Select gasket materials that are designed to resist continuous temperatures of 200 F and above.

Explore BISCO silicone products that offer excellent thermal resistance and are available in a wide range of softness and firmness to meet your specific gasketing needs.

Selecting the right pressure sensitive adhesives for your thermal gasket

Pressure-sensitive adhesives (PSAs) are often used to attach and secure thermal gaskets in place. They’re often made with materials that support gasket performance while also simplifying assembly.

Acrylic PSA

- Benefits: Offers strong, durable adhesion with excellent chemical resistance and ease of die-cutting — making it ideal for sealing applications that require reliable bonding of thermal gaskets to metal or plastic surfaces.

- Considerations: While more affordable than silicone PSA, acrylic adhesives typically perform best in mid-range temperature environments (up to ~350°F).

- Use cases: Securing die-cut gaskets within power supplies, control panels, lighting enclosures and consumer electronics.

Read: Improve EMI Shielding in Electronics with Polyolefin-Based PSA Tapes

Silicone PSA

- Benefits: Provides excellent adhesion and stability at high temperatures (up to ~500°F), along with superior resistance to moisture and chemicals. It also offers compatibility with silicone-based foams.

- Considerations: Generally lower peel strength than acrylic PSAs, but ideal for high-temperature or silicone substrate applications.

- Use cases: Attaching silicone foam gaskets in EV battery packs, industrial enclosures and outdoor-rated electronics.

Keep in mind that compatibility matters when matching adhesives to your substrate. For example, silicone foams require silicone adhesives.

Next steps: Custom die-cut thermal gaskets

Once you’ve selected the best material for your thermal gaskets, bring precision and speed to your assembly process with custom die-cut thermal gaskets.

We begin by laminating your chosen thermal interface material with a compatible pressure-sensitive adhesive. Then, we die-cut the composite to your exact specifications using either traditional dies or dieless digital methods.

Because they’re cut to fit tight spaces, you’ll reduce errors and raise consistency in your electronic assemblies. Simply peel the adhesive backing, place, press — you’re done!

A trusted partner in custom die-cut thermal gasket solutions

When it comes to thermal management, you can count on SRP to manufacture the right gasket for you.

Tell us about your thermal gasket and we’ll get you a fast, accurate quote.