Solving An Electrical Arcing Issue Using Flexible Electrical Insulation Material

Challenge

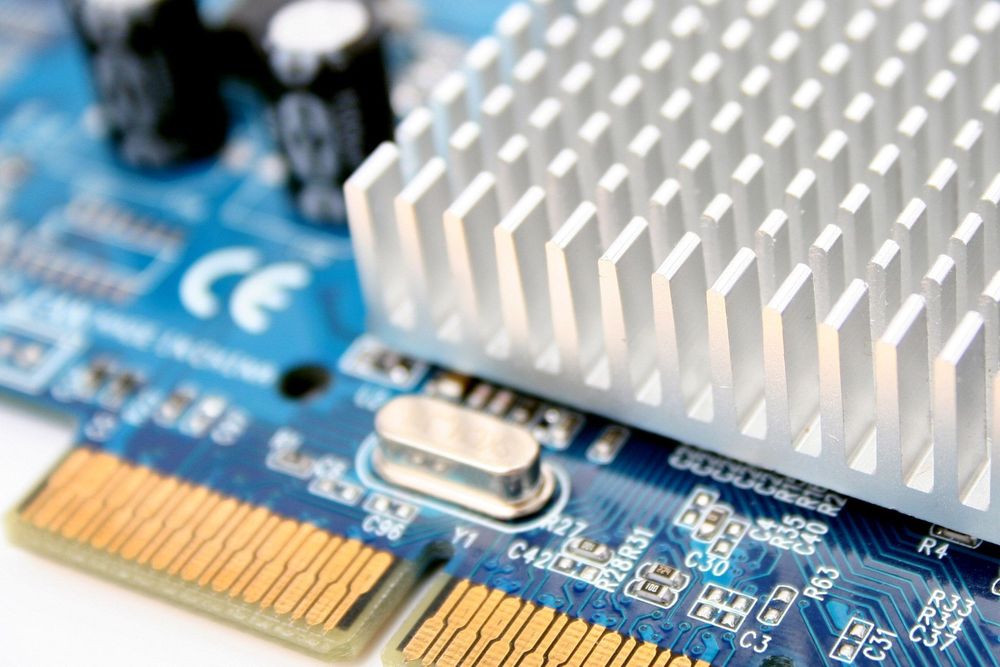

A customer of ours that is an OEM providing controls in the commercial building industry had an application issue concerning a circuit board.

They were experiencing unanticipated arcing on the circuit board that was resulting in failures in the controls. Electrical arcing is a luminous discharge of current that is formed when a strong current jumps a gap in a circuit or between two electrodes.

The major concern with the arcing was not only the fact that it was causing the controls to fail, however, the arcing could also cause electrocution to the user, or potentially start a fire.

Solution

With the knowledge that we were dealing with a circuit board application, we understood that electricity wasn’t the only thing to pay close attention to, but also the heat inside the product. We also knew there was minimal space to work with within the control box.

Our solution to combat all these issues was to use FORMEX flexible polypropylene. FORMEX is a flame retardant material that provides superior electrical insulation and barrier protection in various industrial and consumer electronic equipment.

Results

Using the FORMEX flexible polypropylene, SRP was able to create a spacer that provided electrical insulation to protect the circuit board by preventing the arc gap from arcing to the ground plane.

The flexibility and lightweight features of this material made it extremely easy to incorporate into the building of the control box.

Materials Used

- FORMEX Flexible Polypropylene

Manufacturing Process

- Laser Cutting