High Performance Foam Materials: A Guide to its Uses and Benefits

SRP has been converting foam into gaskets, seals, strips and pads for customers in a variety of industries for many years. Foam gaskets are perfect for applications where cushioning and sealing are a necessity.

What Is Foam Rubber?

Foam is a material that is primarily manufactured in rolls or sheets. During the manufacturing process, the material gets filled with tiny air pockets that give the material its unique properties. Foam can cushion, seal, insulate, and shield a wide range of surfaces and products. It also absorbs shock, vibration, and can resist extreme temperatures.

What Can Foam Do to Enhance Functionality?

Depending on the type of foam, these materials are designed to protect against both the indoor and outdoor environments such as rain, dust, ozone and sunlight.

Foam can be used in extreme temperatures, and can also be used when dealing with oil, gasoline, alkalis, and solvents.

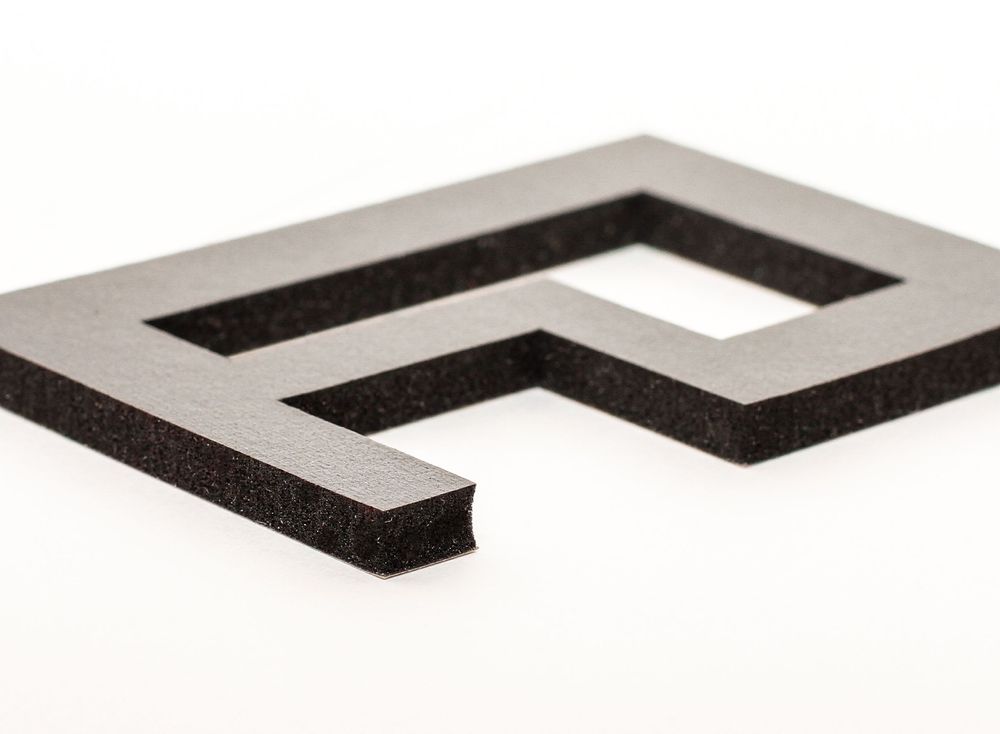

Custom foam gasket products can be die-cut and supplied per customer specifications. We will work with you to develop the perfect solutions to any application issue.

SRP has worked with numerous types of foam products over the years. We commonly convert foam materials such as; Cellular Urethane, Open Cell Polyurethane, Cross-Linked Polyethylene, Crushed Cellular Foam, Closed Cell EVA Foam, and Silicone Foam. Each of these types of foam serve different purposes depending on the application.

Which Foam Material Is Right For Your Application?

If you are unsure about which type of foam is right for your project, feel free to reach out to SRP’s team of specialists for any questions you may have. We will help provide you with the correct material, and would be happy to send any samples or prototypes you may require for testing. We work with our customers to provide the highest quality solutions at the most cost-effective prices.

Ready to finalize your foam? Call us at 800-333-6322 or fill out our online form and we’ll get you answers quickly.