Customizing 3M™ VHB™ Tapes: Get the Right Fit For Your Application

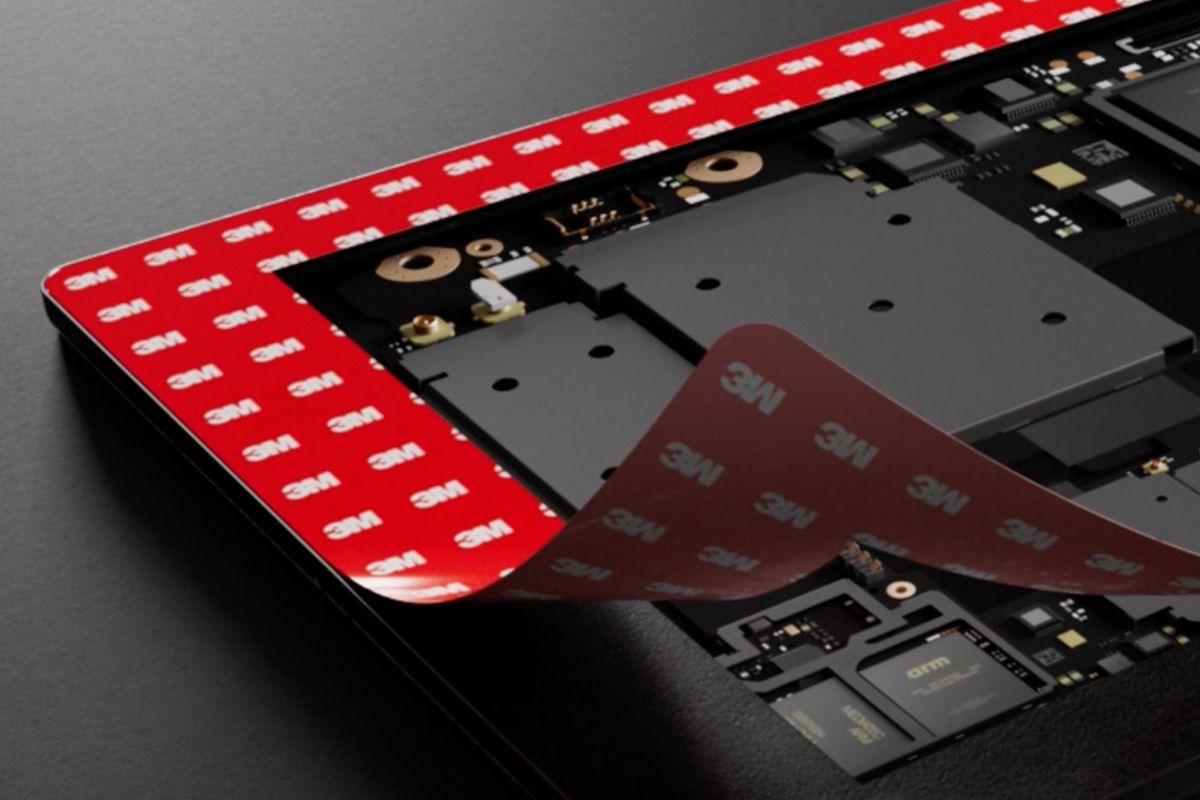

VHB™ foam tape enhances the design and function for a plethora of products. That’s why a wide cross section of industries, including consumer electronics, medical devices, commercial vehicle manufacturing and architecture, have recognized the multiple advantages of VHB™ tape for its enhancements to product design, ease of assembly and long service life.

Because VHB™ is designed to take the place of screws and rivets, choosing the right 3M™ VHB™ Tape product is a critical step in the design process. With multiple VHB™ foam tapes in the 3M™ lineup, a product designer can easily get caught in a rabbit hole of technical sheets and analysis.

Streamline the decision-making process by consulting with the experts who are equipped to identify the best VHB™ foam tape for your application. SRP is a longtime custom converter of VHB™ tape. Our product specialists have the knowledge and training around these adhesives to help you finalize the best tape for your application.

Key benefits of using 3M™ VHB™ Tape

VHB™ tape is one of the most remarkable products to emerge from the 3M™ line of adhesives. In 1980, 3M™ Company introduced an acrylic foam tape capable of joining dissimilar materials and holding them securely in demanding and changing conditions. The name was descriptive and simple: Very High Bond, or VHB™ for short.

Today, the value of VHB™ is still going strong, providing a high-performance bond that’s durable enough to replace traditional fasteners, like screws, rivets and welds.

Benefits of VHB™ tape

- Maintains strength and reliability for the life of the product

- Withstands UV light, moisture, solvents, high and low temperatures, and temperature cycling

- Lightweight and bonds instantly

- Absorbs shock and dampens vibration

- Forms a secure bond between dissimilar materials

For appliances and automotive interiors, 3M now manufactures a low-odor, low volatile organic compound (VOC) emitting family of VHBTM Tape.

SRP and 3M™ VHB: Your solution for high-performance bonding

When your product design is down to choosing and acquiring the best VHB™ product, SRP’s full-service custom converting capabilities have you covered, from final VHB™ tape selection to prototyping to fabrication. Here’s an overview of the services and value we offer.

Expert tape selection

Product selection of your VHB™ tape requires analysis to ensure a fail-safe bond, and that’s where SRP’s expertise and problem-solving abilities come in.

SRP is a longtime 3M™ Preferred Partner. Not only does our partnership enable us to source VHB™ directly from 3M™ at the best prices, but it’s built our unmatched expertise across the VHB™ product line. Over the decades, we’ve developed an extensive knowledge base of VHB™ tapes and how they’re designed to perform in multiple applications.

During the selection process, we’re fully equipped to provide data-driven guidance on the best products for your design. But we’re also one step away from the source of the solution, allowing us to work directly with top product experts at 3M™ to find the answers.

Custom fabrication and formatting

SRP will design a process to fabricate your VHB™ to create the exact part you need, in a format that’s ready for assembly.

- Slitting: Cut rolls of VHB™ into custom widths with the option to slice into custom-length strips for ease of fastening panels, trim, sign and lighting components as well as attaching windows to housing.

- Laminating: Create a custom product by layering VHB™ with other materials needed for assembly and fastening for electronics and appliances.

- Precision die cutting: Cut VHB™ adhesive into unique shapes at high repeatability that conform to your most stringent tolerance requirements. Rotary die cutting offers the option to kiss-cut VHB™ tape to a liner for a peel-and-stick option, which we can format on a roll or with tabs for ease of handling and assembly.

Our years of experience from converting VHB™ is a value add for you, because we’ll draw on our successes to meet and exceed your expectations.

[Download our eBook: Custom die-cut solutions for electronics and appliances with 3M™ VHB™ tape]

Work with a Trusted 3M Converter

When your design calls for the bonding power of VHB™, draw on the expertise of SRP. From expert analysis to fabrication solutions, our custom converting services will bring your product over the finish line.

Send us your CAD file and project requirements to get a prompt and hassle-free quote. Contact us today.