The Upside Of Using Adhesive Transfer Tape in Gasket Bonding

In addition to finding the right gasket material to link two unlike surfaces, finding the right fastener that holds everything together is the next step.

In the making of custom-made gaskets, adhesive transfer tape is the fastener of choice, especially once you compare this option to more traditional fasteners:

Mechanical Fasteners

Bolts, rivets and screws are the mechanical go-to because of the strength but also for the fact they create a bond you can see and feel. On the downside, mechanical fasteners add weight and bulk to your design. During assembly, they create an extra step of labor that requires equipment and a special skill set. Plus, over the life of the product, metal parts can loosen, causing annoying rattling and vibrations during use.

Liquid and Hot Melt Adhesives

Liquid and hot melt adhesives are an effective means to create a strong, lasting bond between two unlike substrates, whether it’s metal to plastic or acrylic to silicone. However, this option requires specialized equipment in-house. Also, drying and curing add time to the production schedule.

Welding

This option provides all the strength of a mechanical fastener, but the result is that slim profile that we like to see. However, welding requires skilled labor, and can’t create bonds of equal strength when joining two dissimilar surfaces.

Why use adhesive transfer tape in gasket bonding?

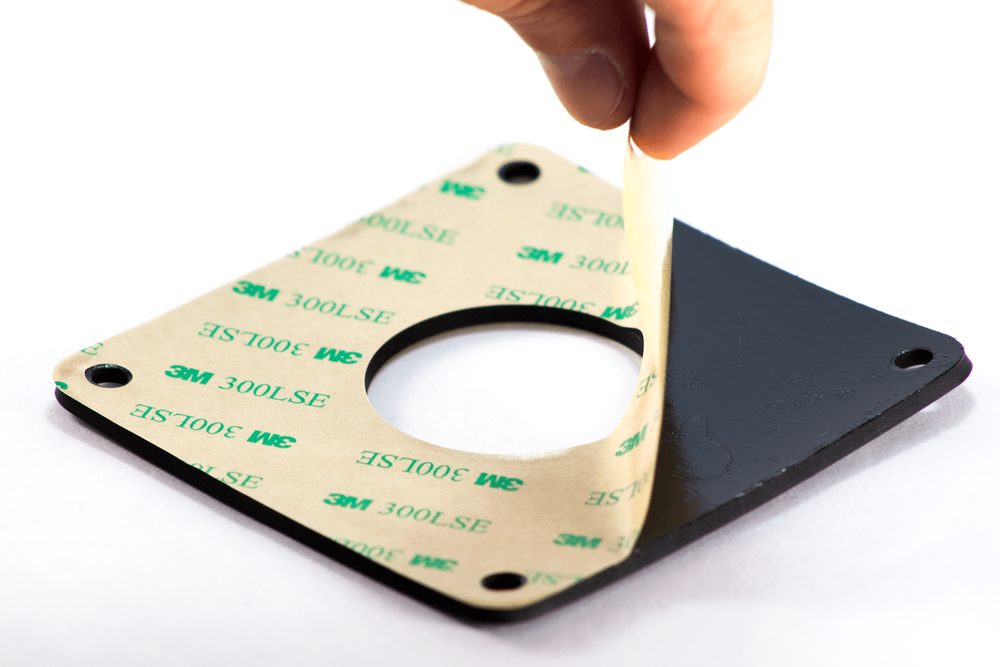

Adhesive transfer tape provides the solution to all the above problems. When adhesive transfer tape is layered on the gasket material and cut to the specified dimensions, it creates the ultimate peel-and-stick solution to your gasketing needs.

Other advantages of using adhesive transfer tape as a gasket fastener:

Streamlines Production

Adhesive transfer tape bonds immediately and builds strength over time. But it requires no drying, no curing, and the item can be handled right after application. Unlike liquid and hot melt adhesive, production can move to the next step.

Low Profile

Adhesive transfer tape is super thin and lightweight, adding no bulk to your design.

Flexibility

Uneven surfaces can be bonded together without the worry of the adhesive losing its grip.

Strength

Stress and pressure are evenly distributed across the gasket surface to provide the best performance.

Versatility

Adhesive transfer tape has no carrier. It’s adhesive placed on a silicone liner that peels away easily when you need it.

Adhesive Transfer Tape: The Ideal Converter Material

Adhesive transfer tape provides a blank canvas for a variety of projects and products. Because its applications are almost unlimited, adhesive transfer tape is the ultimate converter material. Compared to other fasteners, it’s a simple and inexpensive method to join two surfaces.

Adhesive transfer tape is simply a strip of adhesive placed on a liner. When used as a gasket fastener, it’s applied to the gasket material before it’s cut.

During the production of the converter, the liner stays put. Not only does this liner provide a backing material for your peel-and-stick gasket, but during cutting, the liner is an effective means of keeping the adhesive in place. Because the liner minimizes any stretching and moving, this converter method provides complete adhesive coverage. This creates an effective fastener. This also enhances any sealing function you require of the gasket – an important consideration if you’re using solvent- and water-resistant substrates, such as silicone or Neoprene.

SRP is proud to be part of the 3M™ Preferred Converter network. Being a Preferred Converter means we get priority access to the best materials in the industry at the best pricing. We pass these benefits on to our customers.

Learn more about our custom gasket and converter capabilities. Contact SRP and request a quote.