Compression Set in Gaskets: What It Is and How to Prevent It

When manufacturing gaskets, understanding compression set is vital for ensuring long-lasting performance. If a gasket loses its original thickness due to force and pressure, gaps in the barrier can form. These gaps may allow fluids or gases to enter or leak, leading to potential equipment failures.

In this article, we’ll address your most pressing questions about compression set and guide you in selecting the right materials.

What is Compression Set in Gaskets?

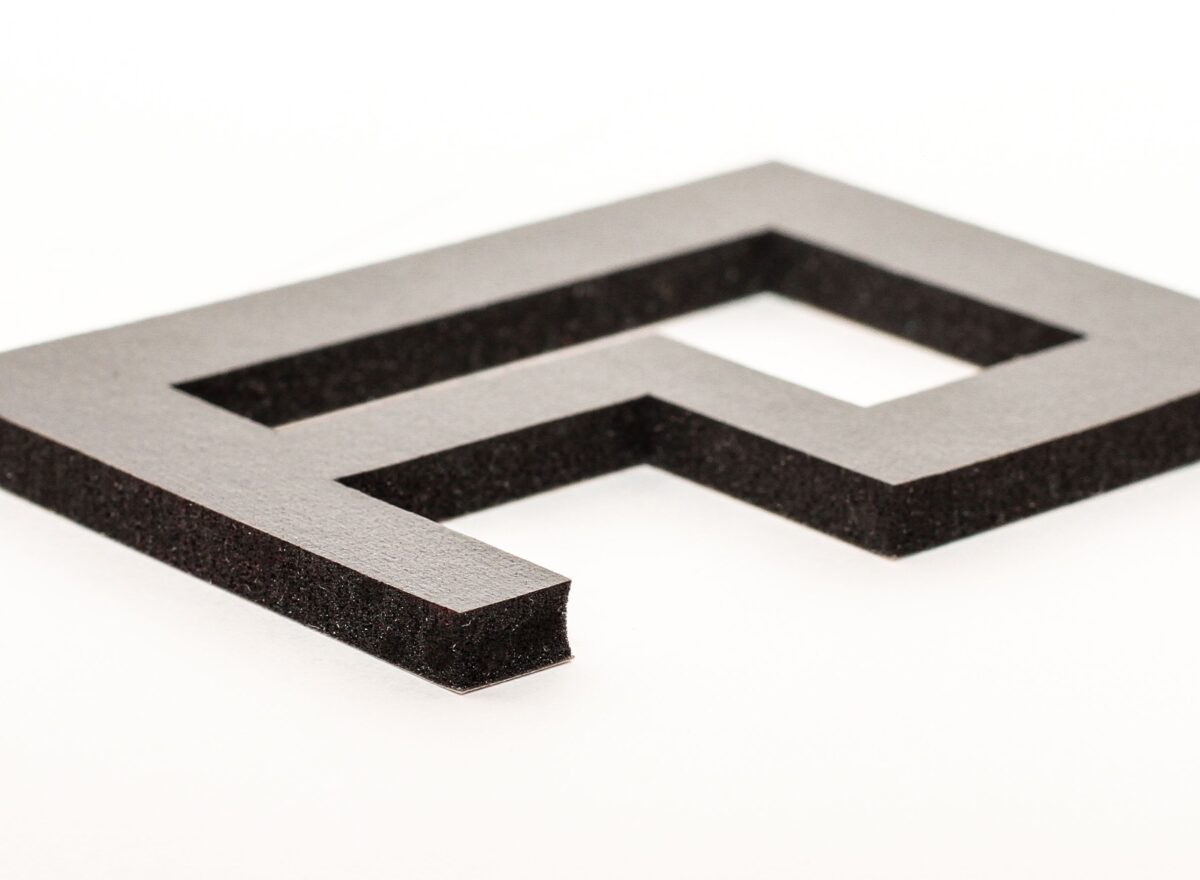

Compression set refers to permanent deformation in foam gasket materials. When made from materials engineered to compress, these gaskets create a dense barrier that seals out moisture, dust and other contaminants.

Over time, continuous pressure can permanently alter the foam, resulting in a permanent loss of thickness. In other words, the gasket doesn’t fully rebound after compression and may no longer maintain a reliable seal. Compression set occurs when a material becomes permanently deformed after prolonged exposure to pressure.

How is Compression Set Measured and Calculated?

Compression set is measured as a percentage. As you compare materials, a lower percentage indicates the material can better withstand long-term pressure without becoming permanently deformed or taking a compression set.

Compression set is calculated by measuring changes in the material’s thickness after it’s been compressed. The calculation is based on the material’s original thickness, recovered thickness and the thickness of the material in a compressed state (test thickness), using the following formula:

Compression Set (%) = [(Original Thickness – Recovered Thickness) / Original Thickness] × 100

A lower percentage indicates the material returns more closely to its original thickness after being compressed, which is preferred for sealing applications that require long-term resiliency.

Reading the data sheets on compression sets

Compression set is evaluated under standardized test conditions, such as ASTM D395 for solid rubber, ASTM D1056 for sponge rubber, or DIN 53517 for cellular foam materials like PORON polyurethane and HyPUR-cel polyurethane.

These standards help ensure that materials are tested under consistent conditions, so you can make fair comparisons between options during material selection.

It’s important to note that compression set values listed in technical data sheets may differ from real-world applications due to controlled lab testing. Use the data to narrow your selection, but always test prototypes to identify the best fit for your specific needs.

SRP offers rapid prototyping so you can launch test use cases immediately.

How Low Should Your Compression Set Be?

Choosing an acceptable compression set value depends on the application and material used. In general, a compression set value of less than 25% is considered adequate for most gasketing applications. However, critical sealing applications, such as medical devices, might call for a lower compression set value of 10%. The same is true for reclosable seals.

For further reading: PORON Selection: Choose the Right Product to Achieve Compression Set Resistance

While it may seem logical to select materials with the lowest compression set for durability, we recommend considering overall value for your specific application. Sometimes, a more affordable material with a higher compression set can perform just as well, making the higher cost unjustifiable.

Our promise at SRP is transparency; we’ll inform you if you’re overspending based on our expertise. Learn more about SRP’s time-tested strategies to control your die-cut gasket costs.

How to Choose the Best Material Based on Compression Set

Selecting the right material to address compression set requires real-world testing to ensure performance under intended conditions.

For reclosable seals — like those on doors or detachable units — a soft material with a low compression set is ideal, as these materials can spring back to their original shape after being compressed.

Many permanent enclosures perform well with materials that have a higher compression set. However, if these enclosures are opened for repairs or cleaning, it’s essential to inspect the gaskets regularly and replace them as needed for optimal sealing performance.

To get more insight on SRP’s added value as you refine material selection, download our case study on our resources page: Identifying the Right Gasket Material to Restore Function to a Gas Detector.

Top-Quality Die-Cut Gaskets: Customized to your Application

At SRP, we combine material expertise with advanced manufacturing techniques to create gaskets that deliver reliable, long-lasting performance.

Have a project in mind? Send us your specifications and we’ll provide a fast, accurate quote.