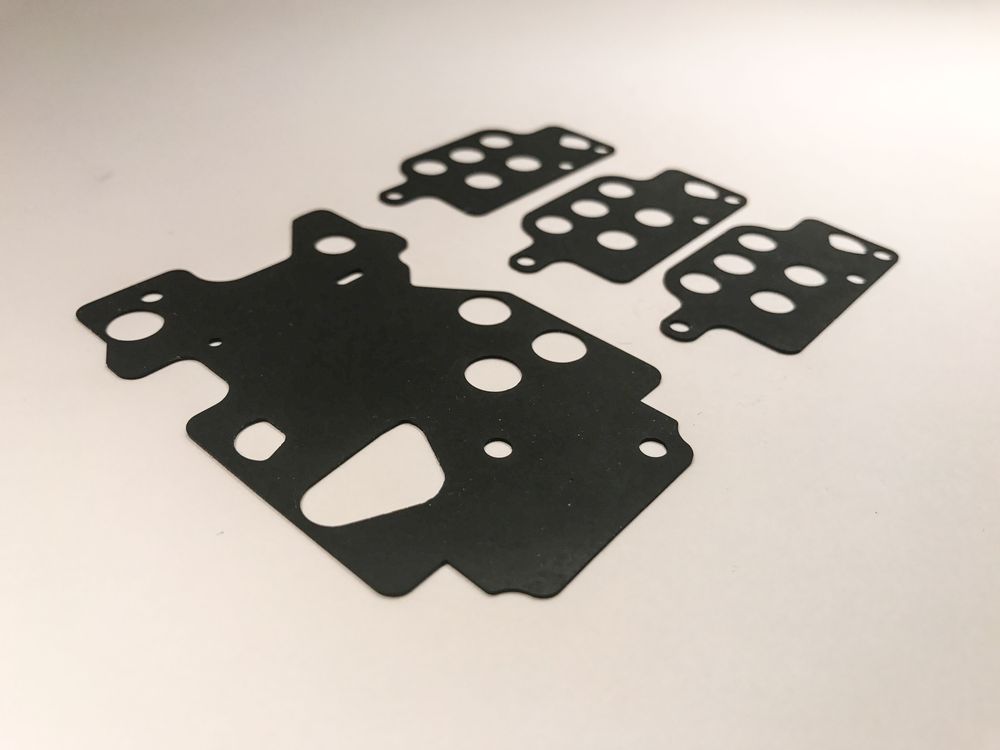

Neoprene Gaskets – Uses and Applications

Neoprene is an extremely versatile material that can be found in virtually every industry, including industrial, electronic, medical and scientific.

It can be die-cut and converted into custom gaskets and seals with pressure-sensitive adhesive options. Neoprene is usually supplied in a sheet or a roll.

What is Neoprene?

Neoprene is an elastomer, a synthetic rubber designed to be flexible, durable and resilient. Also known by its chemical name chloroprene, Neoprene is composed of polymers made of carbon, hydrogen and chlorine.

Why use Neoprene for gaskets and sealing?

Neoprene’s reputation as an all-purpose polymer comes from its long-lasting resistance to tough environmental conditions and its high compressibility, making this elastomer an ideal material for sealing applications.

Benefits of Neoprene gaskets

- Water resistant

- Weather resistant

- Thermal and moisture insulation

- Cushioning and protection

- Lightweight

- Chemical and oil resistant

- Compression resistance

Types of Neoprene Gaskets

A neoprene gasket can come in solid synthetic rubber, sponge or foam, making it an ideal all-purpose material with uses in a broad range of projects. As you consider the desired durometer (hardness and density) of the Neoprene material, keep in mind that different formulations of Neoprene will affect its properties, such as tensile range and compression set.

Solid Neoprene Rubber

A rubber Neoprene gasket can be custom cut from a solid sheet to seal machine doors or to make a weatherproof seal for outdoor equipment enclosures. Because Neoprene resists moisture, oxidation and UV rays, it can stand up to harsh weather conditions, lasting for many years. Simple and fast to die cut, a synthetic rubber Neoprene gasket can be used with a pressure-sensitive adhesive backing.

Applications for solid Neoprene rubber

- Cushioning

- Flame barrier

- Gap filling

- Gasketing and sealing

- LED lighting

- Shock absorption and vibration control

- Thermal

Closed Cell Foam Neoprene Gaskets

A closed foam Neoprene gasket comes in a broad range of thickness and construction, and is often used for environmental sealing, and they’re frequently used for HVAC, automotive and electrical applications.

When used in outdoor equipment enclosures, closed cell foam Neoprene gaskets can effectively seal out dust, dirt and moisture from entering the unit, preventing wear and damage to mechanical parts. Because the material stands up to weather conditions, from UV rays to the hottest temperatures, it provides a long-lasting, durable seal.

Neoprene resists other materials it can be exposed to in an electrical unit, such as oil, refrigeration and solvents.

Applications for closed foam Neoprene gaskets

- Cushioning

- Sound and shock absorption

- Environmental sealing

- Gap filling

Learn more about Closed Cell Foam Neoprene Gaskets

Closed Cell Sponge Neoprene Gaskets

Closed cell sponge Neoprene gaskets have a wide range of uses, from cushioning to vibration control to gaskets. Available in soft, medium and firm densities, Neoprene material is lightweight and durable, standing up to weather conditions, including rain, ice, ozone and UV rays. Closed cell sponge Neoprene also meets certain flame ratings, making it ideal for sealing and cushioning electronic components, while also resisting acids, oils and other solvents.

Applications for closed cell sponge Neoprene gaskets

- Cushioning

- Gap filling

- Gasketing and sealing

- LED lighting

- Shock absorption and vibration control

Learn more about Closed Cell Sponge Neoprene

Open Cell Sponge Neoprene Gaskets

Open cell sponge Neoprene gaskets are often used to absorb shock, sound and vibrations. These come in a variety of degrees of thickness, hardness and grades. This elastomeric material recovers to its fabricated shape after compression and elongation, and is tough and durable when exposed to environmental conditions. This material is also resistant to exposure to petroleum products. Its anti-slip properties hold components in place, making it a good choice for gap filling.

Applications for open cell sponge Neoprene

- Cushioning

- Shock absorption

- Sound absorption

- Environmental sealing

- Gap filling

Ready to get started on your gasket project?

The Neoprene gasket offers a variety of solutions for many different applications. This is an extremely versatile material that can handle some of the toughest conditions.

At Standard Rubber Products Co. (SRP), we custom design gaskets and seals using a variety of materials for customers in many industries. We provide services to the following industries: electronics, industrial, automotive, medical, HVAC, lighting, aviation, aerospace, furniture and more.

Our dedicated team of engineers are ready to assist you with your next project and provide you with the expertise and quality materials for parts and components that meet your exact specifications.